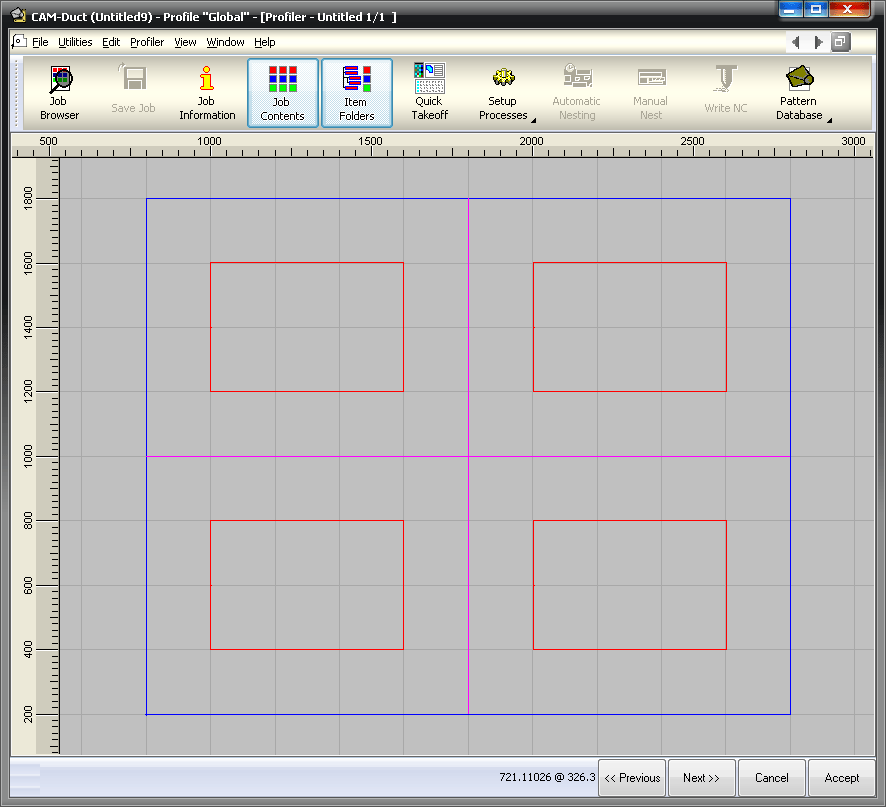

This is used to create an array of parts from a simple part, the parts in the array sharing common cut edges where possible. To access this option Click > Profiler > Common Line Array. This task requires 4 items of information.

- Kerf The width of material removed by the cutting tool. (From the Old English coerf - groove). The default value is picked up from the Machine Set-up information for the tool and material.

- Number of Rows The number of horizontal repetitions of the part.

- Number of Columns The number of vertical repetitions of the part.

- Mirror(m), Rotate(r), Copy(c) Specifies the handling of alternate horizontal repetitions. If Mirror, the part is mirrored left-right. If Rotate the part is rotated 180 degrees. If Mirror or Rotate are selected alternate rows are mirrored top-bottom.

NC can then be written directly from Profiler by going to Profiler - Write NCor the Profile can be saved and Nested as usual.