Most of the 3D strategies in Inventor HSM Pro support rest machining from a solid, an STL, or a stock model. The following is an example of how to choose a solid as your setup stock, and then create a Pocket Clearing operation that uses the setup stock as the rest source.

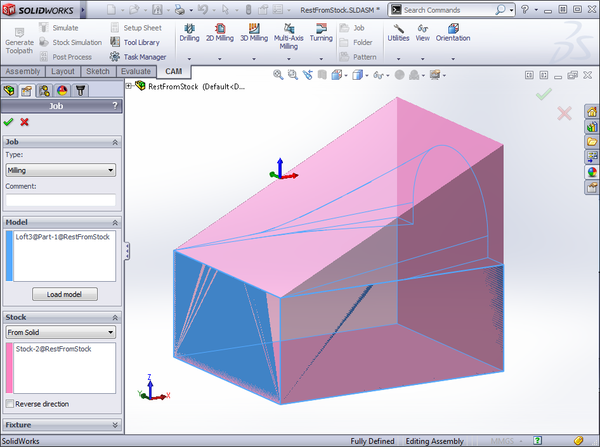

- Set up a machining assembly, adding both the stock part and the model part. It is often a good idea to show the stock part transparent or in wireframe. Important: Another way to accomplish this is to model both the stock and the part as multi-body solids, rather than creating an assembly. This is particularly true if you are using Inventor LT, as assemblies are not supported in that version of Inventor.

- In the Setup, choose the stock and model components in the Stock and Surfaces groups, respectively.

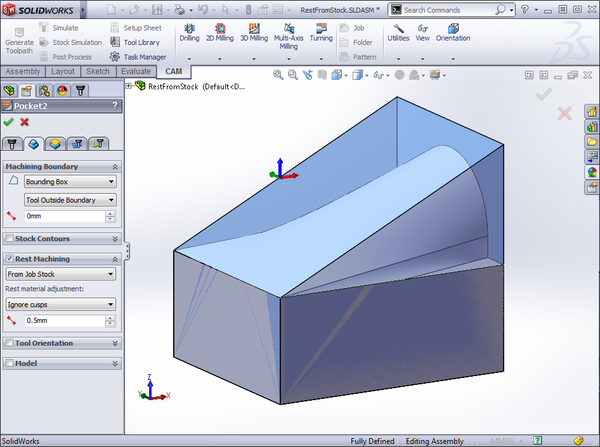

- Create a new operation, e.g. 3D Pocket Clearing, set up the appropriate machining parameters, and then in the Rest machining section on the Geometry tab, activate From Job Stock. Alternatively you can skip step 2, and then select the stock component directly here by choosing From Solid instead. Setting up the stock in the setup, however, has the benefit that it is also used when simulating.

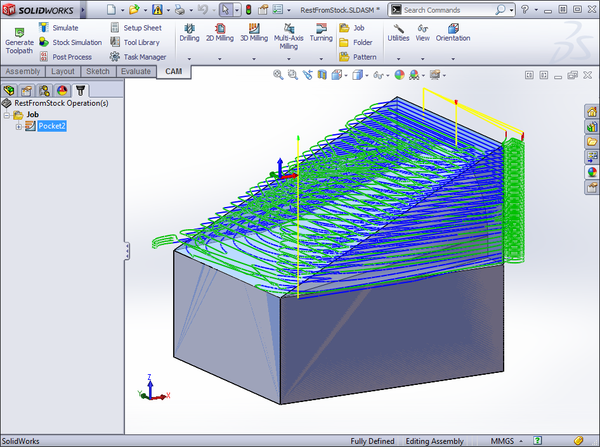

- Click OK to generate the toolpath.