A Microcellular Injection Molding analysis simulates the development of cells in the melt during injection molding.

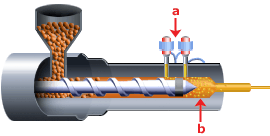

The microcellular foam process, often referred to as MuCell process (developed by Trexel. inc™), works by heating and pressurizing a non-flammable gas such as nitrogen or carbon dioxide to a supercritical state, as illustrated in (a) below, which has characteristics similar to a fluid and produces a foaming agent, as illustrated in (b) below. Once this process has taken place within the barrel, the foaming agent is then injected into the plastic melt as indicated below:

Microcellular molding process

.a) SCF is injected into the barrel/melt through the control valves. b) gas is dissolved in polymer melt to form single phase solution.

Through the injection of the tiny uniform cell structure, higher properties at lower densities is retained more so than is seen with conventionally foamed parts. This allows molding of thin, light parts, producing parts that are not brittle. The reduced amount of resin in the parts also helps reduce cycle times.

In addition, the process reduces clamp force requirements for molding. This is because the super-critical foaming agent acts as a solvent, which lowers the viscosity of the material by 40-60%, so lower pressure is required to push the material into the mold cavity. The process can be run at temperatures as much as 140°F below normal.

The Process

The microcellular processing consists of three main steps:

- Gas dissolution-In the plastication section of the injection molding process, a supercritical fluid SCF of blowing agent (CO2 or N2) is injected in to the polymer to form a single-phase solution. The gas is dissolved in the polymer melt due to applied high pressure.

- Nucleation and bubble growth (foaming). There are two types of processes, either short shot or full shot:

- Short-shot process-The mixture is injected into the mold cavity as a short shot to fill only part of the cavity. Due to the substantial and rapid pressure drop, the solution of the gas in the melt becomes supersaturated and a large number of bubbles nucleate and grow to fill the rest of the cavity.

- Full-short process-The mixture is injected to fill the mold cavity completely. After the cavity is volumetrically filled, it is pressurized and the nozzle is shut off. The material within the cavity then shrinks and foams as the pressure falls.

- Solidification-During the foaming process the mold is continuously cooled down, creating the internal cellular structure. The result is a foamed material with cell size of around 5-100 microns, the actual size depending on processing conditions. The lack of a formal packing phase reduces the residual stress in the material and results in extremely low warpage.

Capabilities

Microcellular Injection Molding analyses can help to:

- Reduce manufacturing costs.

- Improve material processability: reducing the amount of resin in the parts.

- Reduce cycle time.

- Low warpage, and eliminate sink marks.

- Provide useful information to detect various molding problems and to optimize part, mold, and process design in an efficient and cost-effective way.

- Lower the viscosity of the material by 40-60%.

- Mold thin, light parts, producing parts that are not brittle.