Compared to modeling for traditional injection molding, modeling for Gas-assisted Fill+Pack analysis requires more attention to the mesh detail in regions where gas is expected to penetrate.

This requires specific modeling and meshing techniques.

The primary aim of the Gas-assisted process is to get maximum gas penetration without leakage into the cavity walls, and without a blow through to the atmosphere. This requires accurate predictions of the gas flow path and its penetration by the analysis. Such accuracy depends on the geometry of the flow path and the mesh quality.

A gas channel, usually a thick rib, represents the preferred gas path through the polymer. How this path should be modeled and meshed, using either shell or beam elements, depends on the width-to-thickness ratio of the channel.

Gas channels with width-to-thickness ratio > 4:1

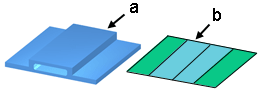

Part designs for gas-assisted injection molding that include ribs, as illustrated in the following figure, typically have a width-thickness ratio greater than 4:1.

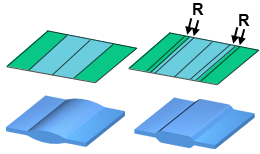

These rib features (a) should be modeled as regions (b) with stepped thickness values according to the rib profile. For optimum modeling of the stepped profile, thickness transition regions should be modeled, as illustrated in the following figure. To avoid solution instabilities, the Flow solver smooths thickness steps over a distance of one element either side of a node on the transition edge. By including transition regions, a better representation of the rib profile is obtained.

In this diagram, the two lower images are geometries as interpreted by the analysis. By modeling transition regions (R), you can define a more accurate shape of the geometry.

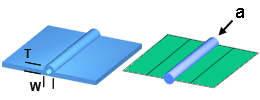

Gas channels with width-to-thickness ratio < 4:1

Where the width-to-thickness (W to T) ratio of the gas channel cross-section is lower than 4, as illustrated in the following figure, the gas channel should be modeled as curves of type Part beam with appropriate cross-sectional dimensions. Beams better account for the effect of heat transfer through the edges of thick ribs which have a width-thickness ratio of less than 4:1. This transfer has a major effect on cooling and frozen layer predictions which, in turn, is a significant factor in defining the route of gas penetration.

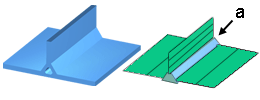

The following figure provides a further example of a gas channel that should be modeled as a beam.

Mesh density

The precision of gas penetration predictions is to within one element of the mesh at any point on the final gas flow front. Therefore, gas channels and adjacent areas where gas is likely to penetrate should have small elements with the lowest possible aspect ratio. The aim is to mesh shell type surfaces so that there is:

- A minimum of 2 elements across each region.

- A minimum of 3 elements across gas channels.

- An aspect ratio of 4 for gas channels, and 6 for everything else.

Small elements can be generated by setting the global edge length value to a low value, or by adjusting the local mesh density in areas of interest.