During Gas-assisted injection molding, the gas can be injected into the polymer melt either through the nozzle of the molding machine, or by direct injection into the mold or into a runner.

This help topic outlines the advantages and disadvantages of each using each method.

Gas injection through the nozzle

The molding machine is fitted with a special polymer/gas injection nozzle through which firstly polymer and then gas is injected into the tool.

- Advantages

- Requires no tool modifications or tool specific components, thus implementation of gas injection molding is relatively cheap.

- Disadvantages

- Gas and polymer are injected through a single location, resulting in less process control.

- Cannot be used with hot runner systems.

- Gas control unit is often tied to a particular molding machine.

- Location and number of gas injection points are determined by the runner system, which is a constraint for mold design.

- Runner system affects the gas flow.

- Very difficult to use with multi-cavity (family) molds, due to difficulties in control of gas and polymer flow paths.

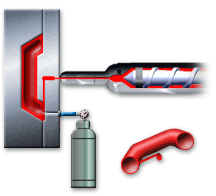

Gas injection directly into the mold or runner

The gas is introduced directly into the runner or cavity by a needle device built into the tool.

- Advantages

- Gas is introduced directly into the cavity, so it can be injected where most appropriate.

- Independent gas injection times and pressure profiles may be set for each injection location.

- Hot runner systems may be used.

- Gas control unit is not molding machine specific.

- Can be used with multi-cavity (family) molds.

- Disadvantages

- Higher tooling costs.