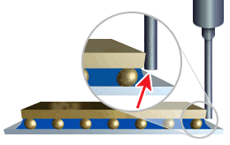

The dispensing location is the point where the encapsulant is dispensed for the underfill encapsulation process.

For an Underfill Encapsulation, ensure that the dispensing location is set along the entire line of one side of the flip chip.

It is important that the correct amount of underfill material is dispensed.

- If too little material is dispensed, the part will not be completely underfilled or may have a fillet that induces stress on the edge of the die. The result is a package with lower reliability.

- If too much material is dispensed, the fillet will extend to unwanted areas on the board or over the top of the die. Reliability of the surrounding components and heat transfer can be adversely affected.

Note: The dispensing location is similar to, and set in the same manner, as the injection location in thermoplastic injection molding.