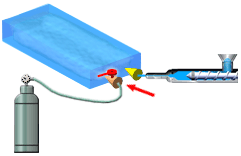

A gas entrance is the position where compressed gas is injected into the mold cavity.

The gas injection stage of the software is an integral component of the filling phase, and allows you to specify single or multiple gas entrances directly into the cavity, or through the polymer injection location(s), that is, machine nozzle or in-runner.

Gas entrance considerations

Gas, like the molten polymer, always flows toward the point of lowest pressure. Therefore, select the gas entrance to ensure that the gas stays in the gas channel, and that the area of lowest pressure is near the end of the gas channel.

Some of the more important questions to consider when setting gas entrances on your model are:

- Polymer injection location(s).

- Along which route will the gas flow?

- How far will the gas penetrate?

- Will gas penetrate into the thin wall section?

- What will the channel and wall thickness be?

- Is the optimum part weight being achieved?

- Will sink marks be avoided?

As with all polymer melt flow analyses, geometry changes in one area can have an effect on the flow characteristics in another section. This is even more significant with gas-assisted injection molding due to the sensitivity with which the pressurized gas searches out and flows through the route of least resistance until such a time as the cumulative resistance of the melt exceeds the pressure of the gas.

For this reason, changes to component geometries must not be looked at in isolation to one another. Due to the complexity of the problem this is only feasible with the aid of a computer based simulation process.