Continuing work on mesh enhancement has focused on optimizing the surface mesh for Dual Domain and 3D technologies.

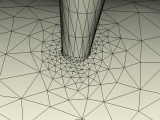

In the past, a surface mesh around small features contained many small, high aspect ratio triangles.

This release introduces a more even surface mesh with a gradation of mesh size from the feature to the surrounding mesh.

As a Dual Domain surface mesh is the basis of a 3D mesh, this improvement also flows through to 3D meshes.

This same technology has also been applied to the following situations.

- Mold surfaces

- The points of contact between the mold surface and cooling lines or feed systems also have the local mesh refinements.

- Gate and beam-cavity connections

- Where the plastic enters a mold is a dynamic region for plastic flow analysis. A more uniform and refined mesh helps capture information from this area.

Compared to the 2014 release:

- For all models tested, the Maximum and average aspect ratio reduced significantly.

- STL models had an improved Match ratio. CAD models had similar Match ratios.

- Element count increased for STL models while CAD models had a similar count.