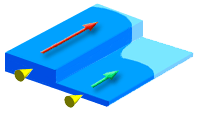

The Average velocity result shows the average magnitude of velocity of the polymer inside the mold cavity over time.

The magnitude of the flow velocity is a straight average through the thickness (but only the melt is considered, not the frozen layer).

Using this result

The Average velocity result can be used to determine areas with a high flow rate. High velocity values for a particular model section could indicate a high flow rate, meaning there could be filling problems such as overpacking or flash. This could also mean that polymer flow is unbalanced, where polymer flows fast through one section and flows slowly through another section of the part.

When the Average velocity result is created as an XY plot, the direction in which velocity is displayed is indicated by the legend values in the top right. For example, E3_X means x component of element 3.

Combined with fill time information, velocity result plots can help you to determine gate locations, runner sizes, and part thickness to achieve a balanced mold and runner design.

Things to look for

- Overpacking.

- Hesitation.

- Racetrack Effect.

- Unbalanced Flow.