After meshing the model, it is strongly recommended that you perform a series of diagnostic checks to ensure that the mesh is suitable for analysis.

- Mesh Statistics

- Mesh Repair Wizard

- Mesh Diagnostics

- Element aspect ratios ideally should be below the following limits:

- 8:1 for triangular elements in Midplane and Dual Domain meshes.

- 30:1 for triangular elements in a Dual Domain mesh that will be converted to a 3D mesh.

- 50:1 for tetrahedral elements in a 3D mesh.

- In a Dual Domain model, the mesh match ratio must be above 85% for flow analysis, and above 90% for warpage analysis.

- In Midplane and Dual Domain models, significant thickness changes must be represented with at least three rows of elements to ensure accurate prediction of flow issues such as hesitation or racetracking.

Optionally, you can remove small features like corner blends and radii from Midplane and Dual Domain models to reduce the computing time. These features can be analyzed in 3D models, with a very high mesh density and little overall change in the results.

A good mesh is critical for accurate results. The recommendations below will help you to evaluate the mesh and clean up the model.

Visual Inspection

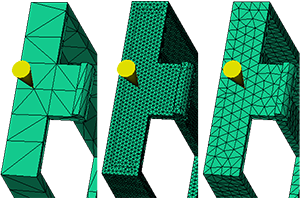

Visual inspection of a Dual Domain mesh

- The first mesh is a bit coarse (has few elements), and therefore, the mesh match ratio may be low and this mesh may not represent part thickness changes well.

- The second mesh has many more elements than necessary; this will result in a long computing time.

- The third mesh has about the right number of elements. There are several rows of elements on the side, and the elements are approximately equilateral triangles, which indicates acceptable aspect ratios have been achieved.

Mesh Statistics

Once the visual inspection has determined the mesh density looks right, use the Mesh Statistics report to determine if the quality of the mesh is acceptable.

- Entity counts.

- Edge details.

- Orientation details.

- Intersection details.

- Surface triangle aspect ratio.

- Match percentage (Dual Domain models only).

- Nodes (Number).

- Elements (Tetras: Number, Volume, Aspect ratio, Maximum dihedral angle; and Beams: Number, Volume).

- Total volume.

Once a problem has been identified in the mesh statistics, corrective action can be taken to fix the problem.

Mesh Diagnostics

The diagnostics tools show more detailed information about the problems listed in the Mesh Statistics report.

- Aspect Ratio Diagnostic (Midplane and Dual Domain models only).

- Beam L/D Ratio Diagnostic.

- Overlapping Elements Diagnostic. This includes intersecting and overlapping elements (Midplane and Dual Domain models only).

- Orientation Diagnostic (Midplane and Dual Domain models only).

- Connectivity Diagnostic.

- Free Edges Diagnostic. This includes free and non-manifold edges (Midplane and Dual Domain models only).

- Collapsed Faces Diagnostic (Dual Domain models only).

- Dimensional Diagnostic (3D models only).

- Thickness Diagnostic (Midplane and Dual Domain models only).

- Occurrence Number Diagnostic.

- Zero Area Elements Diagnostic (Midplane and Dual Domain models only).

- Dual Domain Mesh Match Diagnostic (Dual Domain models only).

- Beam Element Count Diagnostic.

- Trapped Beam Diagnostic.

- Centroid Closeness Diagnostic.

- Cooling Circuit Diagnostic.

- Bubbler/Baffle Diagnostic.

When a diagnostic is displayed, the Diagnostic Navigator toolbar is automatically displayed. This allows you to quickly zoom on elements in the model that were detected by the diagnostic.

Mesh Repair Wizard

After you have evaluated the mesh using visual inspection, mesh statistics and mesh diagnostics, you need to fix the identified problems in order to have a clean model before you run an analysis. This can be done with the Mesh Repair Wizard.

The Mesh Repair Wizard runs a series of diagnostics on your model and, for each diagnostic, allows you to fix any problems detected.

- Stitch Free Edges.

- Fill Hole.

- Overhang.

- Degenerate Elements.

- Flip Normal.

- Fix Overlap.

- Collapsed Faces.

- Aspect Ratio.

- Inverted tetras

- Collapsed faces

- Insufficient refinement through thickness

- Internal long edges

- Tetras with extremely large volume

- Tetras with high aspect ratio

- Tetras with extreme angle between faces

Validate the repairs

Whenever an automatic fix is applied to the mesh, the repairs must be validated to ensure that no new problems were created.

After you have completed the mesh clean up, it is recommended that you run the Mesh Statistics report again, and if necessary, run the Mesh Repair Wizard again to confirm that all potential problems have been resolved.