Transient cool analyses are used to simulate the change in mold temperature with time. Transient from production start-up cool analyses simulate the mold temperature variations from the initial production start-up cycle when the mold is cold, until the mold temperature stabilizes and reaches its optimum operating conditions.

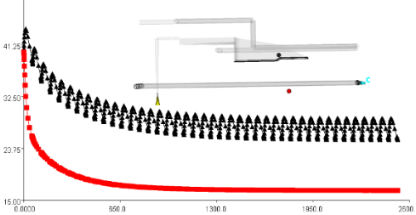

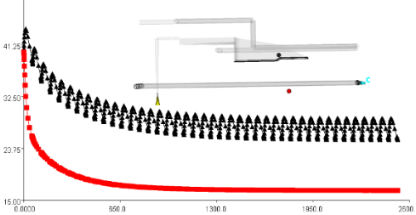

When an injection molding machine is commissioned to manufacture a product, it may require many cycles before the mold reaches its optimum operating conditions. The Transient from production start-up cool analysis sequence will show the number of cycles required before the mold reaches these optimum operating conditions. In the example below, the black node on the mold is near the part and is affected by the in-cycle temperature variations. The red node is further from the part and is unaffected by in-cycle variations. It took 42 iterations for the mold temperature to reach steady-state.

Note: Transient cool analysis sequences are only available for 3D mesh types.