Shear stress is stress that is experienced by the melt as it flows through the mold. It occurs as a result of friction between layers of plastic flowing in the cavity.

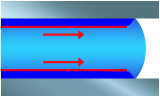

Shear stress increases with increasing material flow rate, or with increasing material viscosity. It often manifests around the gate due to high injection speeds, and at the end of flow if a constant flow rate is used. High shear stress can cause the plastic to degrade and fail due to stress cracks. The red line in the following diagram represents the area of maximum shear stress. This is between the dark blue frozen layer and the light blue melt.

What to do

To reduce internal shear stress:

- Decrease the flow rate.

- Use programmed injection speeds.

- Increase wall thickness.

- Avoid differential orientation and differential shrinkage.