The option to calculate fiber breakage when performing a fiber orientation analysis using a long-fiber composite material has been implemented.

The fiber breakage model implemented was first proposed by Phelps and Tucker [1] as a statistical model which describes the probability of a fiber breaking due to buckling and shearing forces in a flow field.

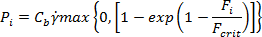

For a single fiber, the probability of breaking under the hydrodynamic forces can be expressed as:

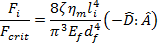

where the force ratio is the hydrodynamic compression force, described by Dinh and Armstrong [2], versus the critical buckling force, such as:

where  and

and  are the deformation rate tensor and fiber orientation tensor, respectively. Other variables are the properties of the fiber and matrix, except for

are the deformation rate tensor and fiber orientation tensor, respectively. Other variables are the properties of the fiber and matrix, except for  which is the drag factor.

which is the drag factor.

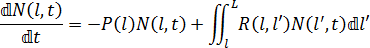

The fibers, broken or not, have to follow a conservation law because they cannot disappear nor can they grow in a flow field. This conservation law can be expressed as:

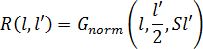

where L is the initial fiber length, N(l,t) is number of fibers with length l at time t, P(l)is the scalar probability function of fiber length l, and R(l,l') is the probability function of fiber length l breaking to form a fiber of length l' (where l'<l). It can be expressed as a Gaussian breakage profile, such as:

where  is the Gaussian normal probability density function for the variable l with mean l'/2 and standard deviation Sl'. S is a dimensionless fitting parameter that can be used to control the shape of the Gaussian breakage profile.

is the Gaussian normal probability density function for the variable l with mean l'/2 and standard deviation Sl'. S is a dimensionless fitting parameter that can be used to control the shape of the Gaussian breakage profile.

References

- Phelps, J.H., Processing-microstructure Models for Short- and Long-fiber Thermoplastic Composites. Ph.D. thesis, University of Illinois at Urbana-Champaign (2009).

- Dinh, S.M. and Armstrong, R.C., A Rheological Equation of State for Semi-Concentrated Fiber Suspensions. J. Rheol., 28(3):207-227 (1984).