The Pressure at V/P switchover result is generated from a Fill analysis, and shows the pressure distribution through the flow path inside the mold at the switchover point from velocity to pressure control.

Using this result

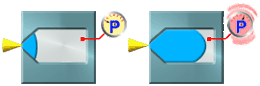

Pressure should be zero at the extremities of each flow path at the end of filling.

Things to look for

During the filling stage, large variations in the pressure distribution, indicated by closely-spaced contours, should be avoided.

Normally the maximum injection pressure at the nozzle is about 140 MPa (20,000 psi). We recommend having a maximum pressure of 100 MPa (14,500 psi) for the mold (part and feed system) and 70 MPa (10,000 psi) maximum for the part. There are many molding machines with higher pressure capacities. If you don't know what the pressure capacity is, assume it is 140 MPa. If the pressure capacity of the molding machine is known, use no more than about 75% of the pressure capacity for a design guide for the entire mold, and 50% for just the part.

There will be zero pressure at the flow front, and some portion of the part is not filled. The portion not filled as shown in this plot will be filled under pressure control as defined in the process settings.