There are two transient cool analysis products for studying mold temperature fluctuations; transient within cycle and transient from production start-up. In both cases, the Cool (FEM) solver determines the results using the finite element method for calculation.

- Transient within cycle cool analyses

- This solver simulates mold temperature deviations from the cycle average. The typical injection molding cycle consists of the filling, packing, cooling and mold open stages.

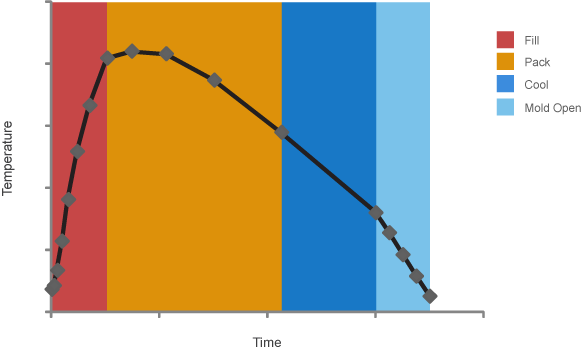

Change in temperature of mold during an injection molding cycle

During the filling stage the high temperature molten plastic is injected into the mold cavity at high pressure. This causes the temperature of the mold to rise. Following injection, the molten plastic cools down as a result of the cooling channels in the mold, until it reaches a cool enough temperature that the plastic part can be ejected from the mold at the commencement of the mold open stage. As a result, the temperature in the mold also decreases. As shown in the graph above, therefore, the mold temperatures rise during the filling and packing stages but drop during the cooling and mold open stages. The transient cool solver can be used to simulate the mold temperatures at different stages of the injection molding cycle.

- Transient from production start-up cool analyses

- This solver simulates the mold temperature variations from the initial production start-up cycle when the mold is cold, until the mold temperature stabilizes and reaches its optimum operating conditions.

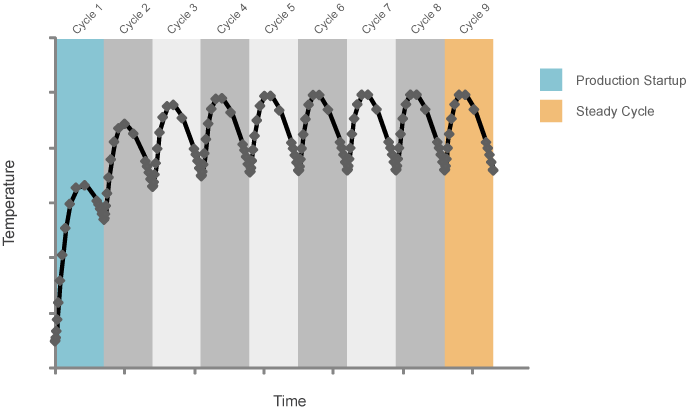

Change in temperature of mold from one cycle to the next during a production start-up routine

When an injection molding machine is commissioned to manufacture a product, it may require many cycles before the mold reaches its optimum operating conditions, or stable cycle. Once the stable cycle has been reached, the mold temperature within a cycle still changes, as shown in the transient within cycle graph, but is constant between cycles as shown in the graph above. Until the stable cycle has been attained, the quality of the part cannot be guaranteed. The transient from production start up solver simulates the process leading up to the stable cycle and helps predict how many cycles will be required.

The Cool (FEM) solver can also be used for a 3D Cool analysis. This provides a similar solution to the Cool (BEM) solver if the conduction solver is selected, but in a shorter timeframe. If the flow solver is selected, the results can be used to capture shear heating effects from flow, that are caused by heat fluxes from the part into the mold.