The surface of your model must be assigned the property type "compression surface" to run a compression type molding process.

Manual assignment of compression surfaces

If the automatic option does not assign the compression surfaces properly, then you can try assigning the surfaces yourself. The software determines the property of the various model surfaces, based on the property of the surface nodes. Nodes are either interior to the selection or on the boundary.

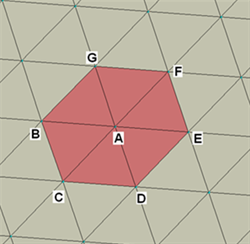

Types of surface node as defined for the compression surface properties

where A = interior node B-G = boundary nodes, red elements = compression (moving) surface, and beige elements = fixed surface.

- Interior node

- An interior node, illustrated by A above, is one which is completely surrounded by the selection of elements. This node is given the same property as the surrounding elements, in this case 'moving'.

- Boundary node

- A boundary node, as illustrated by B-G above, is one which is on the boundary of the selected elements. It could be surrounded by elements with different compression surface properties. In the figure above, node B is surrounded by both compression (moving) surface elements and by fixed surface elements.

Assignment Examples

In the example above, there are seven (7) nodes associated with this selection of six (6) elements that we want to assign the compression (moving) surface property. We also want to assign the property 'fixed surface' to the beige elements.

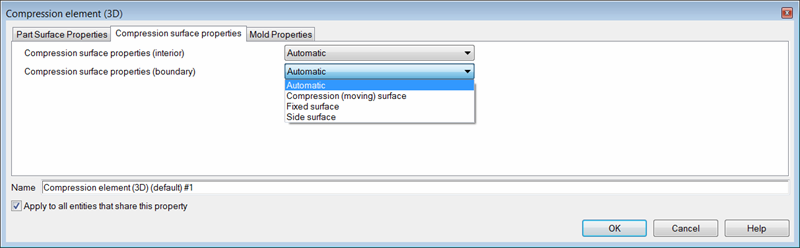

- You specifically define only the interior nodes in the compression element (3D) dialog

- If you only change the interior setting to reflect the moving surface selection and the fixed surface selection, then nodes B-G, which are on the boundary between the two will be assigned automatically by the software.

- You specifically define both the interior and boundary nodes in the compression element (3D) dialog

-

If you select the red elements above and assign both the interior and boundary nodes the compression (moving) surface property, then nodes A-G will all have that property.

If you select all the beige elements above and assign both the interior and boundary nodes the fixed surface property, then all the beige nodes, and nodes B-G will be assigned the fixed surface property.

Since there is now a conflict between the assignment of those boundary nodes, a priority listing is assigned by the software, in the order: