Distribution networks typically involve several pipes or ducts connected to each other in series or in parallel.

When dealing with internal fluid flow through pipes and ducts, the engineering objective is to ensure that these fluids can be delivered to a point in the network at a specified flow rate and pressure at minimal cost.

Pipes in series

In a series pipeline, fluids are subjected to various resistances such as friction which is caused by the roughness of the pipe, and minor losses which are caused by a change in the diameter or the shape of the pipe, for example when the fluid flows through fittings, elbows or valves.

These frictional and minor losses result in a general pressure loss.

Pipes in parallel

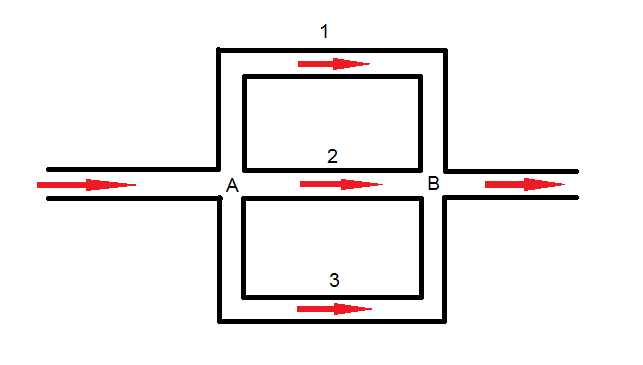

With parallel connections, the distance that the fluid must travel can be longer in certain regions of the network. In the figure below, more fluid will flow through branch 2, because the flow always follows the path of least resistance.

In this case the total flow through the network is the sum of all three branches.

- The conservation of mass throughout the system must be satisfied. This principle is known as the Continuity Principle.

- The pressure drop between two junctions must be the same for all paths between the two junctions. This principle is known as the Energy Principle.