At room temperature, an unloaded plastic part already has non-zero self-strains caused by cooling of the structure from its elevated temperature, either in the mold or after being injected. The non-uniform cooling of the part causes the structure to warp.

Fiber-filled materials have another factor compounding the cooling process. At the constituent level (fiber/matrix), additional strain is developed which is caused in part by differences in the thermal expansion characteristics of the constituents and the anisotropic nature (e.g. stiffness changes) of the structure due to the spatially varying fiber orientations. For additional details on warping in plastic parts, refer to the Warp analysis section in the Moldflow help.

Advanced Material Exchange can be used to predict the warpage that occurs in the part as a result of these residual strains, prior to any externally applied mechanical or thermal loads. In this case, the thermal residual strains contribute to the total strain state of the composite material and thus influence the mechanical load level at which the material fails.

To include the effects of thermal residual strains in the structural analysis, you must:

- Run Moldflow with the Fill + Pack + Warp analysis sequence

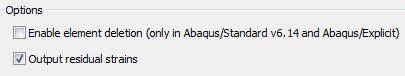

- Request the output of Residual Strains in the export dialog

If the Output residual strains check box is turned on, Advanced Material Exchange will create a HIN file with the following keyword during the export sequence.

*CURE STRESS

The HIN file (.hin) is an auxiliary text file that can be used for special analysis features such as modeling warpage. The HIN file will be exported with the exact same name as the input file (.cdb, .dat, or .inp) and structural interface file (.sif) with a .hin extension. The HIN file is placed in the same directory as the input and structural interface files before you run the analysis.

The modeling of warpage is very sensitive to element selection and mesh density. Whenever possible, use higher-order elements (i.e. C3D10M or 187) and avoid using 4-noded tetrahedral structural elements. If you plan to simulate warpage frequently, it is recommended that you perform a sensitivity test on the mesh density and element type and correlate the results to experimental data.

Using Residual Strains to Predict Warpage

If you turn on the Output residual strains check box, it is important to understand how to use the information in your structural analysis. The residual strain data should be used to predict the warpage in the part that results from the manufacturing process. The residual strain data should not be applied during the mechanical loading step(s) to help drive failure. Let's look at the typical workflow for how to use residual strains:

- Turn on the Output residual strains check box in the export dialog.

- Create an initial unloading step in the structural model where the residual strains can be applied in order to predict the warped shape of the part. The unloading step should use the same boundary conditions as the mechanical loading step. The unloading step can be applied over a single increment.

- Create the mechanical loading step. The mechanical loading step should use several increments to apply the load to the warped part. Multiple increments are necessary so that the stress field resulting from the unloading does not have a large influence on the material model. 100 increments is a recommended starting point for mechanical loading.