Now that our model is constrained, we can apply an additional boundary condition to impose a vertical displacement on the top surface of the coupon. We choose to load the coupon with a displacement load because it results in a more gradual failure process than a similar load using an applied force. When a coupon like this begins to fail under the action of an applied force, it fails rapidly because the load continues to increase as the load carrying capability of the structure decreases. With a displacement controlled loading, the load carried by the coupon decreases as the structure fails which allows for a slower rate of failure.

First we need to create an equation constraint so that we can easily determine the total reaction force during post-processing.

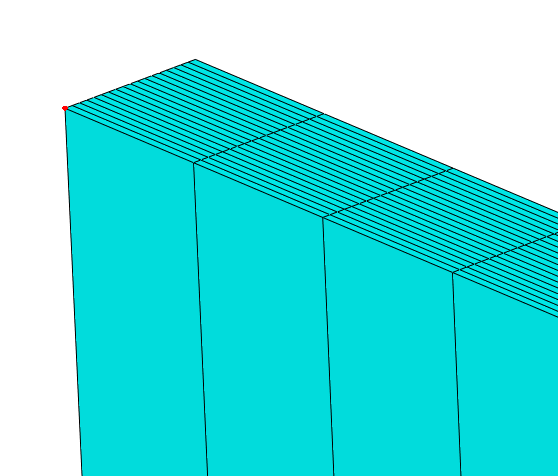

- Create a node set () named Load_Node. Select the node highlighted below.

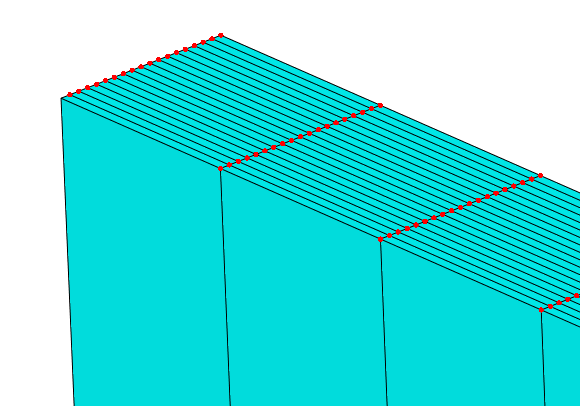

- Create a second node set named Tied_Nodes. Select the remaining nodes on the top surface of the coupon.

Tip: To quickly select these nodes, enable "by angle" selection and select all nodes on the face, then switch back to "individually" selection mode and deselect the Load_Node by clicking it while holding down the Ctrl button.

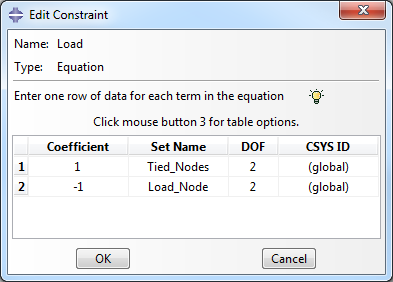

- Switch to the Interaction module.

- To constrain the y-direction displacement of the Tied_Nodes to the Load_Node, select and select the Equation type. Fill out the Edit Constraint dialog so that it appears as shown below.

- Switch to the Load module and create a Displacement/Rotation type boundary condition in the Load_Step named Displacement. When prompted to select a region, choose the Set option and select the Load_Node set.

- Enter 0.12 as the value for U2.