Predict the progressive failure response of the composite structure using four finite element models.

The models differ only in the number of elements distributed through the thickness of the sandwich panel, i.e., the materials, element type, in-plane mesh density, and boundary conditions are exactly the same in each model. The four different levels of through-the-thickness mesh density are listed below. Each of the four models uses C3D8R elements.

- Original model: 1 element to capture core and 1 element per facesheet that captures the entire layup (3 elements through-thickness).

- 1st modification: Increase the core mesh density to allow 4 elements to capture the core profile (6 elements through-thickness).

- 2nd modification: Increase the facesheet density to allow 2 elements to capture the layup of each facesheet (8 elements through-thickness).

- 3rd modification: Increase the facesheet density to allow 4 elements to capture the layup of each facesheet (12 elements through-thickness).

Ideally, a very fine through-thickness mesh would be utilized to provide the most accurate loading distribution and deformation throughout the model, but run time costs often limit mesh densities.

Models

EP1_1elemFace_1elemCore.inp

- Element type: C3D8R

- Through-thickness mesh density:

- Composite Facesheets: 1 element

- Foam Core: 1 element

EP1_1elemFace_4elemCore.inp

- Element type: C3D8R

- Through-thickness mesh density:

- Composite Facesheets: 1 element

- Foam Core: 4 elements

EP1_2elemFace_4elemCore.inp

- Element type: C3D8R

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

EP1_4elemFace_4elemCore.inp

- Element type: C3D8R

- Through-thickness mesh density:

- Composite Facesheets: 4 elements

- Foam Core: 4 elements

Results

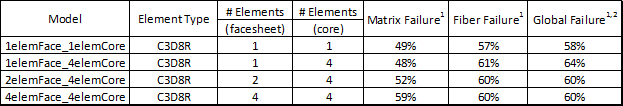

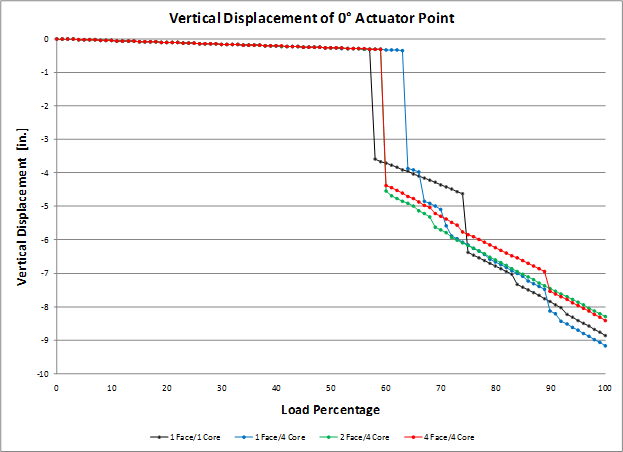

The table below displays the load level at which each type of failure event is predicted by the four models. The plot below shows the overall vertical load-displacement curves for the composite structure.

- Load percentage is on a 0-100% scale

- Global failure is defined as a large discontinuity in the load-vertical displacement curve for the 0° application point of the load head shown previously

After comparing mesh density results, we can make the following observations:

- As the through-the-thickness mesh density is increased, the initiation of localized matrix and fiber failure is predicted to occur at higher load levels.

As we progressively increase the number of elements through the thickness of the laminate, the transverse shear stiffness of the model decreases faster than the in-plane stiffness of the model. Consequently, as the through-the-thickness mesh density is increased, the model tends to exhibit an increase in transverse shear deformation at the expense of in-plane deformation. The net result of this trend is that the magnitude of the peak in-plane stresses tends to decrease as the through-the-thickness mesh density is increased, thus localized failure is predicted to occur at higher load levels.

- Global failure is only slightly affected by mesh density.

Despite the fact that increasing the through-the-thickness mesh density results in delayed local failure initiation for both the matrix and the fiber, the predicted global structural failure load is not significantly affected by the through-the-thickness mesh density. This observation suggests that the escalation from local failure initiation to global structural failure occurs faster as the through-the-thickness mesh density is increased. It is reasonable to expect local failures to progress into global failures more rapidly for a higher density mesh (as seen in the table above). A denser mesh results in a more refined failure path for a structure due to the increase in number of Gaussian integration points for failure criterion to be evaluated at. A more refined failure path facilitates a more rapid progression of failure, hence the rapid progression of local failures into global failures.