View results of the thermal analyses.

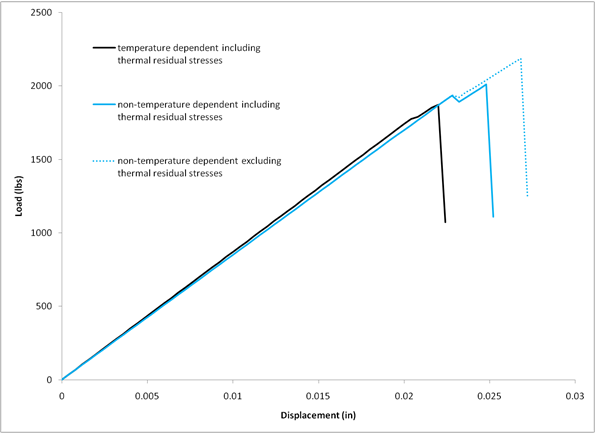

The load-displacement curves for the models are shown below. All models have very similar stiffness values with the temperature dependent (TD) model having a slightly higher stiffness. The TD model has a slightly higher stiffness because the measured E11 and E22 values increase from 72°F to 260°F and the TD model uses properties at 140°F, compared to the other models which use properties at 72°F.

The TD model fails at 1872 lbs, the non-TD model that includes thermal stresses fails at 2011 lbs, and the non-TD model that excludes thermal stresses fails at 2187 lbs. The TD model fails early because the interpolated compressive strengths -S11 and -S22 at 140°F are lower compared to the compressive strengths at 72°F.

A comparison of the non-TD failure loads shows that including the constituent level thermal stresses decreases the failure load by 8%.