Complete these steps to generate an analysis report of machine data, including utilization.

- Open the DWG layout from which you wish to derive a report.

- Click Generate Report

on the Material Flow drop-down menu on the Factory tab.

on the Material Flow drop-down menu on the Factory tab. - Name the report file and click Save.

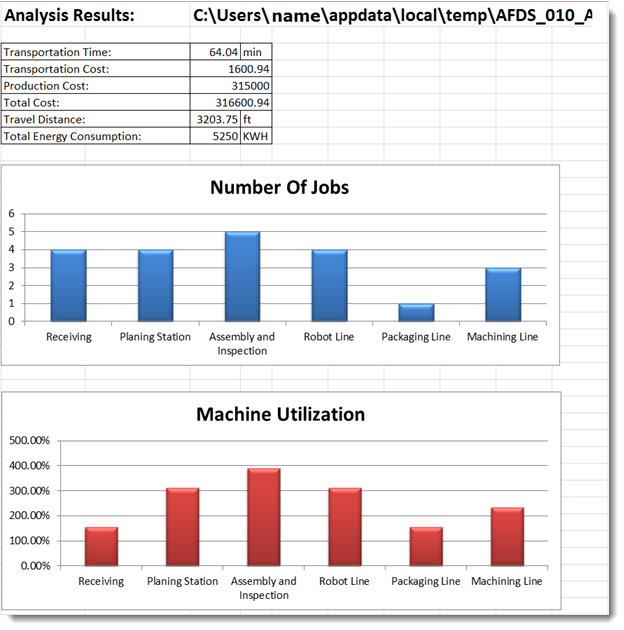

Interpreting Report Results

| Transportation Time |

For continuous transportation types: If (setup time + processing time) * batch size < (length of the connection line/travel speed) sum of (setup time + processing time) * batch size for all jobs Otherwise: sum of (length of the connection line / travel speed + load time + unload time) * (roundup(part quantity of the job/batch size)) for all jobs For non-continuous transportation types: sum of (length of the connection line / travel speed + load time + unload time) * (roundup(part quantity of the job/batch size)) for all jobs |

| Transportation Cost |

For continuous transportation types: If (setup time + processing time) * batch size < (length of the connection line/travel speed) sum of (setup time + processing time) * batch size * transportation cost rate for all jobs Otherwise: sum of (length of the connection line / travel speed + load time + unload time) * (roundup(part quantity of the job/batch size)) * transportation cost rate for all jobs For non-continuous transportation types: sum of (length of the connection line / travel speed + load time + unload time) * (roundup(part quantity of the job/batch size)) * transportation cost rate for all jobs |

| Production Cost |

(setup time * setup cost rate + processing time * processing cost rate) * part quantity at each operation for all jobs |

| Total Cost |

total transportation cost + total production cost |

| Travel Distance |

For continuous transportation types: sum of length of the connection line * (roundup(part quantity of the job/batch size)) for all jobs For non-continuous transportation types: sum of length of the connection line * (roundup(part quantity of the job/batch size)) for all jobs Note: If bidirectional, the distance will be doubled

|

| Total Energy Consumption (kW.h) |

(setup time + processing time) * part quantity * energy consumption rate at each operation for all jobs |

For daily desired production rate:

Machine Utilization for a station = ((setup time in minutes + processing time in minutes ) * daily desired production rate for all jobs at the station / (number of shifts * shift hours * 60 * percent uptime)) * 100%

For hourly/minute/second desired production rate:

Machine Utilization for a station = ((setup time in minutes + processing time in minutes) * minutely desired production rate for all jobs at the station * percent uptime) * 100%