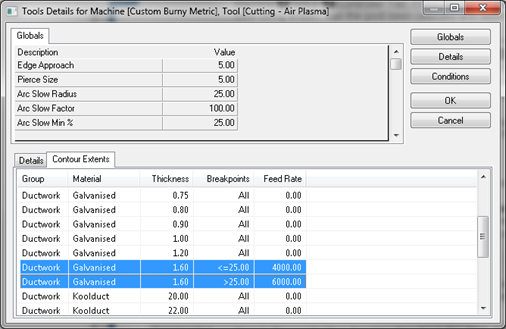

Custom NC machines and some of the machine specific posts also support Conditions. Conditions can use any of the parameters, adding a condition creates a new tab (for example, the "Contour Extents" tab shown below) which displays the parameters applicable to the condition. Conditions are used with breakpoints or rules to control how the parameters are used in different circumstances.

The right-click menu provides the following options:

Edit allows the selected parameter values to be changed.

New Breakpoint adds a new break relating to the condition.

Remove Breakpoint removes the current breakpoint.

New Rule adds a new rule relating to the condition. Rules are usually selected by the user when NC is written.

Remove Rule removes the current rule.

Copy copies the selected parameter values to the clipboard.

Paste replaces the selected parameter values with ones from the clipboard.

Delete deletes the selected parameter values.

In the example shown above, a 25 mm breakpoint has been added to Galvanised 1.5 mm material in the "Contour Extents" condition. Small contours (for example, holes) less than 25mm in extent will be cut at the 4000mm per minute feed rate. Larger contours will be cut at the 6000mm per feed rate.

Another example where conditions might be used is to select different parameter values for different laser technologies, different main and/or shield gases for high-definition plasma torches, or different lead in lengths.