Custom shaped mills are collectively know as Form Mill tools and can be created in the Tool Library from a sketch, or a revolved solid body saved in a separate Autodesk Inventor or Inventor LT part file.

To create a form mill, follow these steps:

- Create a new Inventor part.

- Create a sketch with a single closed profile that represents the cross-section of the tool.

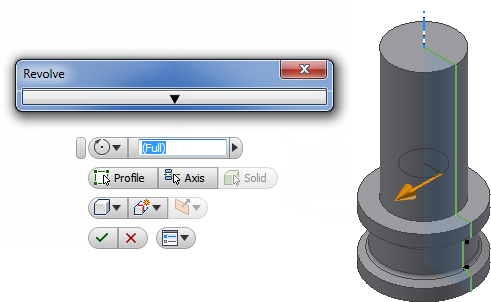

- Use the Revolve command to create a revolved feature from the sketch.

A revolved feature in an Inventor part; suitable for creating a Form Mill tool

- Save the part file.

- Open the Inventor HSM Tool Library.

- Create a new mill tool by clicking the New Mill Tool button.

- Click the Cutter tab and choose Form Mill from the Type: drop down menu.

- Click Import File...

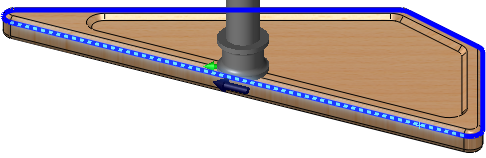

- Browse to and select the tool file you saved before. The sketch profile is loaded as the profile for the form mill, and previewed as shown here.

The Form Mill dialog box with preview. The dotted lines show the toolpath compensation point, which is controlled by the diameter and tip offset.

Using the tool is done similarly to all other tools, keeping in mind that the toolpath is created in relation to the compensation point defined by the diameter and tip offset.

Selected geometry for a 2D Contour using the tool with compensation point

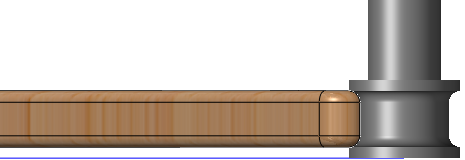

Simulating with form mill tool

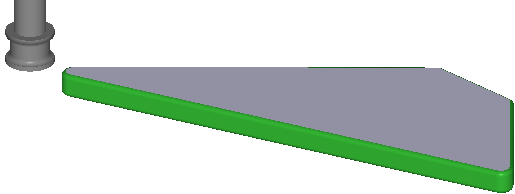

Stock simulation with form mill tool