|

Access: |

Ribbon:

CAM tab

Toolpath panel

Toolpath panel

Post Process

Post Process

|

Post processing is the process used to convert the machine-independent cutter location data into machine-specific NC code that can be run directly on CNC machines.

When post processing operations, the cutter location data and associated metadata, like the job description and operation comments, are transferred into the post processor. It is the full responsibility of the post configuration to convert all this data into meaningful NC code. The configuration is free to ignore any of the input data or to output extra data not directly derived from the cutter location data.

Inventor HSM ships with customizable post processor configurations for all the commonly available CNC controls/machines. Generic post processors include Fanuc, Heidenhain, Haas, Hurco, Mazak, MillPlus, Okuma, Siemens, Yasnak, and many more. The post processor configurations can be updated to fit your exact requirements.

Inventor HSM includes a highly flexible and fast post processor based on the JavaScript programming language to perform this critical task. JavaScript should not be confused with Java which is a very different programming language. The post processor is used for both NC programs as well as setup sheet generation.

The post processor has been designed primarily for the purpose of text-based output, so whenever you need to interchange data with other applications you should choose a text-based format to simplify the post development when possible.

The post processor has been highly optimized for performance and you should generally see your NC programs being generated within seconds (with the output commonly exceeding 6-7Mb/s). Naturally, the actual performance depends highly on the individual post configuration.

Usage

To post process toolpaths, first select the desired operations in the CAM Browser and then, from the ribbon, click

CAM tab

Toolpath panel

Toolpath panel

Post Process

Post Process

. The Post Process dialog box is displayed to allow configuration of the post processor.

. The Post Process dialog box is displayed to allow configuration of the post processor.

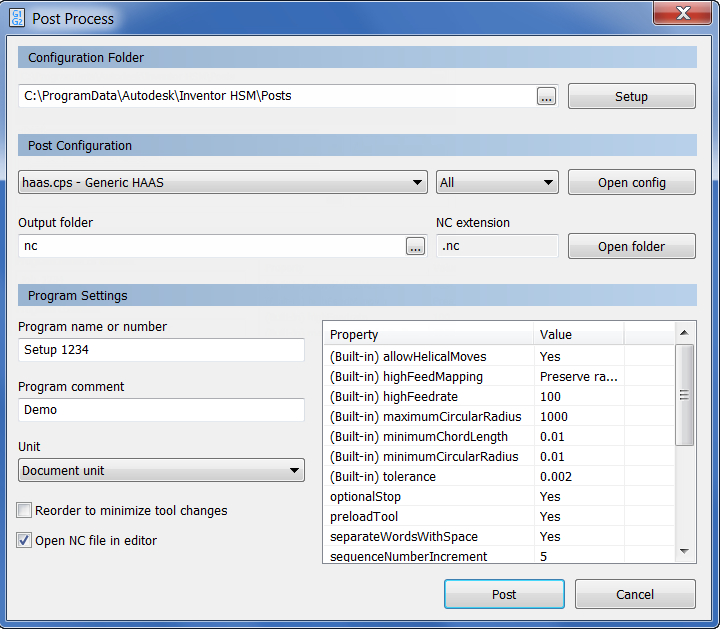

The Post Process dialog box

By default, Inventor HSM is configured to use the generic post configurations that are installed with Inventor HSM. It is recommended that you create a dedicated folder at an appropriate place for the customized post configurations to ensure that the configurations are not lost when upgrading Inventor HSM at a later time.

When the Post Process dialog box is first opened, it scans the folder containing the post configurations for default properties and makes all working post configurations available to you.

To post process, you must first choose the desired post configuration, enter an appropriate program name and comment, setup the user-defined properties if required, and finally click the Post button. Modified user-defined properties are highlighted in bold and blue. The entered post processing properties are preserved between posting sessions so you only need to set your preferences once. However, if a post configuration is modified some parameters may have to be reentered.

Please note that the post processing time can vary greatly depending on the complexity of the post configuration and the size of the toolpath. Generally, post processing should complete within a few seconds. The post processor runs as a background task making it possible to keep working while the NC code is being generated. The post processor task is listed in the Inventor HSM Task Manager. If the post processing fails (e.g. if the program name is not supported), the error message can be viewed from the task manager by opening the task log.

If the Open NC file in editor check box is activated, the generated NC code is then opened in the preferred editor as defined in the CAM preferences. Alternatively on failure, the post processing log is opened in the selected editor. The NC editor installed with Inventor HSM is used as the editor by default.

When posting multiple jobs, the jobs are executed in the order given in the CAM Browser. You can enable the Reorder to minimize tool changes check box to direct the post processor to reorder the operations to minimize the number of tool changes.

Configurations

Inventor HSM comes with many different general purpose post processor configurations that can be modified to fit the individual requirements of users. Due to the great diversity of the various CNC machines, the general purpose configurations often cannot be used directly.

Inventor HSM makes use of a fully customizable and fast post processor. This allows users to configure the post processor for their individual needs. For additional information on development of post processing configurations, please consult the post processing documentation which accompanies Inventor HSM.