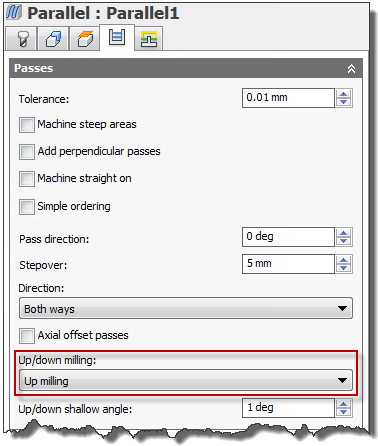

Machining strategies like Pencil, Scallop, Parallel, Radial, and Spiral produce toolpaths that move up and down in Z. Depending on the tools used, you might prefer to only do down milling or up milling. Inventor HSM lets you control this on this Passes tab with the Up/down milling drop-down menu.

Controlling Up/down milling

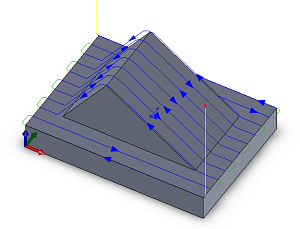

Up/down milling = Don't care (the default)

The default setting is Don't care which means that Inventor HSM does both up and down milling. This is the most efficient approach since it minimizes the amount of linking and machining time.

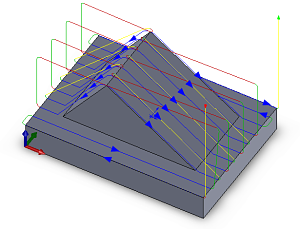

Up/down milling = Down milling

Down milling is useful if you are using a long thin tool and are machining near steep walls.

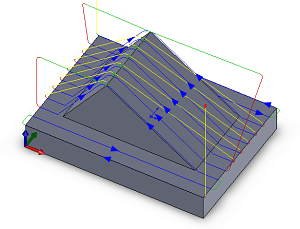

Up/down milling = Up milling

Up milling is useful if you are using a tool which cannot cut with the bottom.

When using either up or down milling, you can set the additional Up/down shallow angle.

The Up/down shallow angle value specifies the smallest wall angle to do up/down milling on. Any surface with an angle less than this is machined as if Don't care was selected, that is, either up or down depending on the direction the tool is already moving.