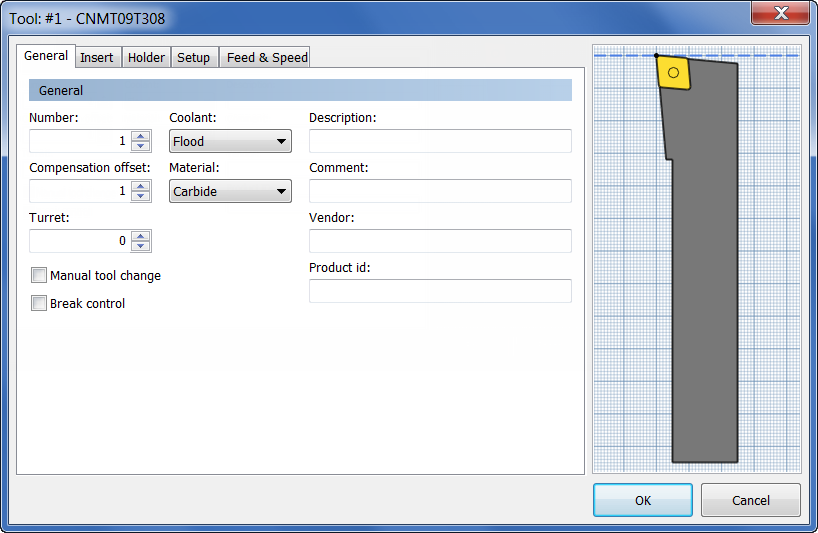

The New Turn Tool dialog box lets you edit an individual turning tool and is divided into five tabs:

- General - Number, offsets, description etc.

- Insert - The shape of the cutting part of the tool.

- Holder - Definition of holder shape.

- Setup - Setup parameters.

- Feed & Speed - Parameters for cutting and non-cutting feedrates and spindle speed.

The preview on the right side of the dialog shows the shape of the tool and is automatically updated to reflect changes to the tool.

General tab settings

Number:

The number used to select the tool on the CNC machine.

Compensation offset:

The index of the tool compensation offset used for turning.

Turret:

Specifies the turret of the tool.

Manual tool change

Enable to force a manual tool change on machines with an automatic tool changer.

Break control

Enable to check for tool breakage after use.

Coolant:

The type of coolant used with the tool.

Material:

The tool material.

Description:

A textual description of the tool. This description is included in the tool name shown throughout Inventor HSM.

Comment:

A text comment for the tool. The comment is typically included in the post-processed output.

Vendor:

The vendor of the tool. Use this to identify the specific tool used.

Product ID:

The vendor's identifier (ID) for the tool. Use this to identify the specific tool used.

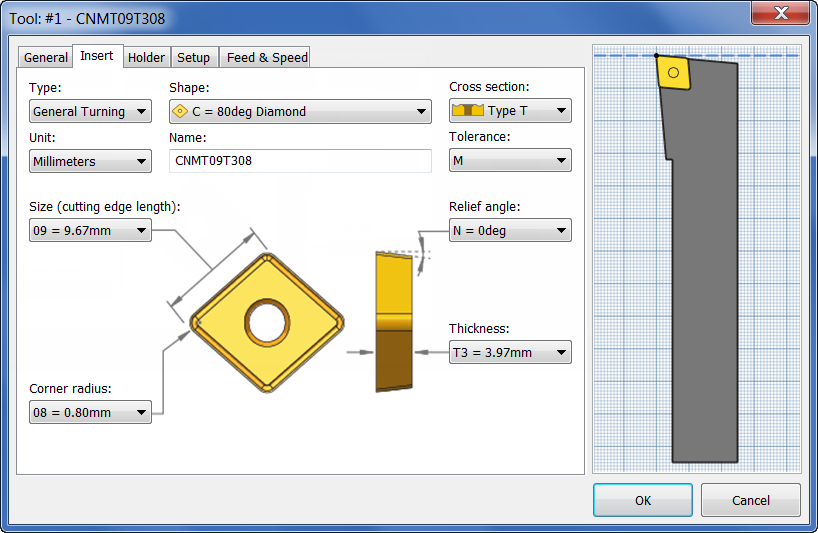

Insert tab settings

Type:

The type of the tool.

Unit:

The tool unit (Millimeters or Inches).

Shape:

Specifies the shape of the insert.

Name:

Coding system of numbers and letters to describe the insert shape, dimensions, and important parameters.

Size (cutting edge length):

The size of the insert.

Corner radius:

The corner radius of the insert.

Cross section:

Specifies the hole and chip breaker shape of the insert.

Tolerance:

This is how much variation is allowed in the dimensional size of the insert.

Relief angle:

Specifies the draft on the face(s) of the insert that contacts material during machining.

Thickness:

The thickness of the insert.

Overall length:

Specifies the entire length of the tool.

Groove width:

Specifies the nose diameter of the grooving tool.

Width:

Specifies the width of the tool.

Thread pitch:

The pitch of the tap thread, specified as the vertical distance between the teeth of the tap.

Internal thread

This option enables the machining of internal threads.

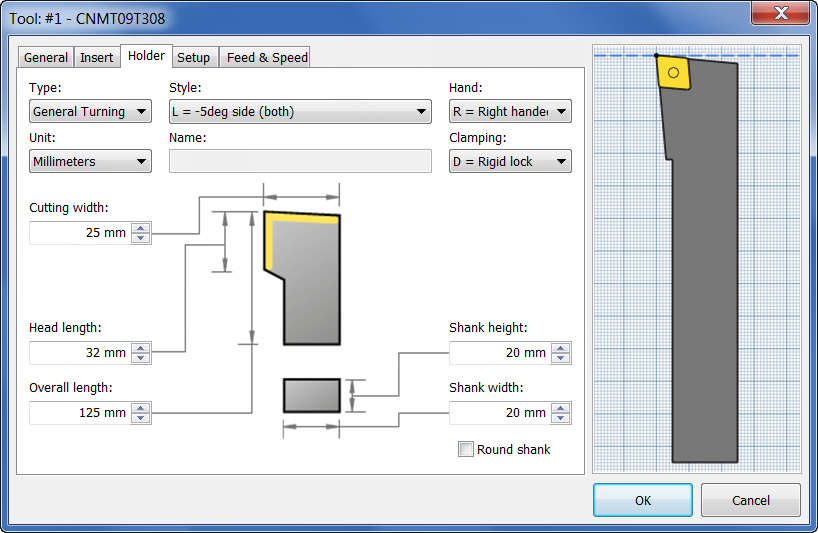

Holder tab settings

Type:

The type of the tool.

Unit:

The tool unit (Millimeters or Inches).

Style:

Specifies the shape of the holder.

Hand:

The side of the tool with respect to the part.

Clamping:

Specifies how the insert is fixed to the holder.

Cutting width:

The width of the holder head.

Head length:

The length of the holder head.

Overall length:

Specifies the entire length of the holder.

Shank height:

The height of the holder shank.

Shank width:

The width of the holder shank.

Round shank

Enabling this option specifies a cylindrical shank for the holder.

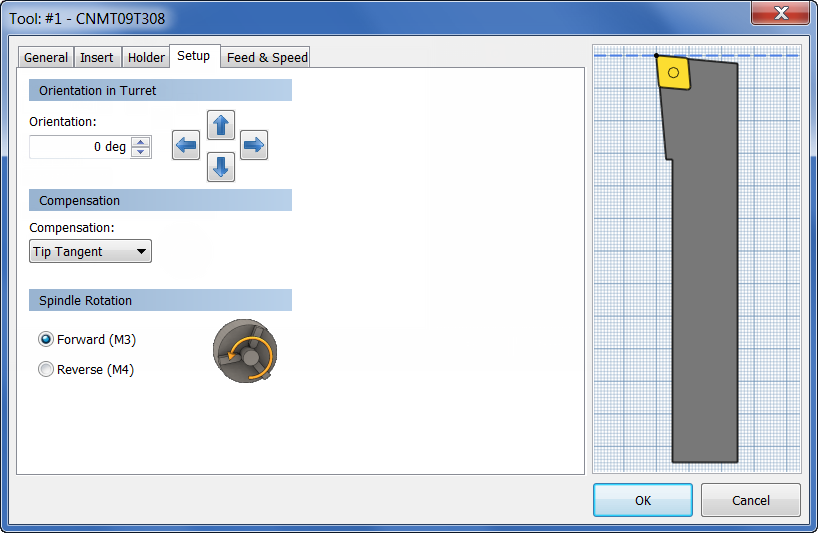

Setup tab settings

Orientation:

The angle of the tool with respect to the cutting direction.

Compensation:

Specifies the compensation type for the tool.

Forward (M3)

The spindle rotates clockwise.

Reverse (M4)

If selected, spindle rotation is reversed.

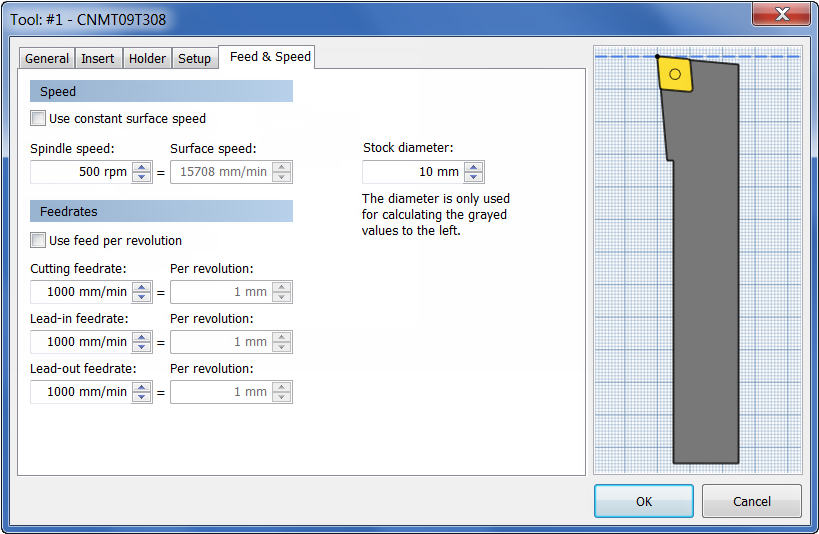

Feed & Speed tab settings

Speed

Use constant surface speed.

Spindle speed:

The rotational speed of the spindle.

Surface speed:

The spindle speed expressed as the speed of the tool on the surface.

Feedrates

Use feed per revolution.

Cutting feedrate:

Feed used in cutting moves.

Lead-in feedrate:

Feed used when leading in to a cutting move.

Lead-out feedrate:

Feed used when leading out from a cutting move.

Diameter:

The diameter of the cutter.