Input Parameters

Gear type - internal or external gear

Gear ratio and tooth numbers

![]()

Pressure angle (the angle of tool profile) α

Helix angle β

Module m (for metric calculation)

Diametral Pitch P (for English units)

Unit addendum a *

Unit clearance c *

Unit dedendum fillet r f *

Gear widths b 1 , b 2

Unit corrections x 1 , x 2

Summary of unit correction Σ x = x 1 + x 2

|

Auxiliary Geometric Calculations |

|

Design According to the Strength Calculation |

|

Design of Gearing Width |

Calculated parameters

Gearing number

|

for i > 1 |

||

|

u = i |

||

|

for i < 1 |

||

|

u = 1 / i |

||

Tangential module

|

|

Normal pitch

|

p = π m |

Axial pitch

|

p t = π m t |

Base pitch

|

p tB = p t cos α t |

Helix angle on the basic cylinder

|

sin β b = sin β cos α |

Axial pressure angle

|

|

Rolling/working pressure angle

|

|

Axial rolling/working pressure angle

|

|

Pitch diameter

|

d 1,2 = z 1,2 m t |

Base circle diameter

|

d b1,2 = d 1,2 cos α t |

Theoretical center distance

|

|

Real center distance

|

|

Feed factor/addendum lowering

|

|

Outside diameter

|

d a1,2 = d 1,2 + 2m (a * + x 1,2 - Δ y ) |

||

|

- for internal gearing the interference check is done as well |

|

|

|

for km > 0 is accomplished by addendum lowering d a2 = d a2 - 2km |

Root diameter

|

d f1,2 = d 1,2 - 2m (a * + c * - x 1,2 ) |

Work pitch diameter

|

|

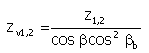

Virtual Number of Teeth

|

|

Virtual Pitch Diameter

|

d n1,2 = z v1,2 m |

Virtual Base Circle Diameter

|

d bn1,2 = d n1,2 cos(α) |

Virtual Outside Diameter

|

d an1,2 = d n1,2 + d a1,2 – d1,2 |

Tooth thickness (measured normally on the pitch diameter)

|

s 1,2 = p/2 + 2m x1,2 tg α |

Tooth width on the chord (measured normally)

|

s c1,2 = s 1,2 cos 2 α |

Addendum height above the chord

|

|

Unit addendum width (measured normally)

|

where:

|

Operating width of gearings

|

b w = min( b 1 , b 2 ) |

Relative width

|

|

Factor of mesh duration

|

ε γ = ε α + ε β |

||

|

Factor of profile mesh duration |

||

|

|

||

|

(the minus sign applies to internal gearing) |

||

|

Factor of step mesh duration |

||

|

|

||

Minimum correction without tapering

|

where: a 0 * = a * + c * - r f * (1 - sin α) |

Minimum correction without undercut

|

|

Minimum correction with the allowable undercut

|

|

Checking chordal dimension

|

W 1,2 = ((z w - 0.5) π + z 1,2 inv α t ) m cos α) + 2 x 1,2 m sin α where: |

|||

|

z w |

is the tooth number across which the measure is performed |

||

Checking size across rollers/balls

|

- for even tooth number |

|||

|

M 1,2 = D s1,2 + d M |

|||

|

- for odd tooth number |

|||

|

M 1,2 = D s1,2 cos(90 / z 1,2 ) + d M where: |

|||

|

d M |

wire (ball) diameter |

||

|

|

diameter of the wire center circle |

||

|

|

wire (ball) contact angle |

||