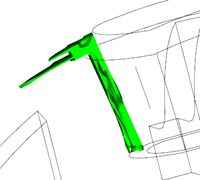

The meeting of flow fronts can cause weak points within the part. The Weld surface formation (3D) result is the representation, through the thickness of the part of where this occurs.

Depending on the part configuration and injection locations, a weld surface could be formed at any stage of the filling phase. Because of this, the Weld surface formation (3D) result can be animated over time.

This result is a representation of where weld surfaces are initially formed and is similar to the weld lines result.

While based on the same angle of incidence as the weld lines, the 3D nature of the result means that factors such as the number and aspect ratio of the tetrahedral elements feeding into a node, along with the parabolic nature of the flow front need to be considered before assigning a weld surface.

To properly investigate a weld surface, one or more of the following may be required.

- A finer mesh

- Shorter solver time steps

- More frequent results output

The analysis will have to be re-run for any change to take effect.

- To generate shorter solver time steps, decrease the Maximum %volume to fill per time step, (). The default is 4%.

- To get more frequent results output select Write at constant intervals or Write at specified times from the Intermediate results panel and edit as required

Using this result

While the weld surface effect on the surface of a part can impact the appearance of the finished product, it is often the location and extent of a weld surface through the thickness of the part that will impact on the structural strength.