The main problem caused by non-uniform cooling is warpage.

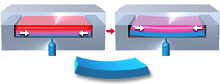

The following diagram shows how the bottom layer cools first. As this layer shrinks it slides under the top layer which is still molten. As the top layer freezes it becomes fixed to the shrinking bottom layer and it cannot slide over it. The resulting tensile stress can cause the part to warp.

What to do

The acceptable temperature difference between the top and bottom sides of an area depends on how easily the part will warp. For example, a part with ribs will be less likely to warp. The geometry of the part is one factor that determines the acceptable temperature difference between the top and bottom of an area.

Consider the following specific areas in the mold:

- Hot spots-try to achieve more uniform cooling

- Spacing between the cooling channel and mold cavity.

- Spacing between adjacent cooling channels.