The Microcellular Injection Molding analysis uses a bubble nucleation model to simulate the microcellular foam injection molding process and predict the filling pattern and weight reduction that can be expected from using this process.

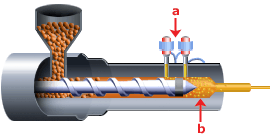

In this process, a supercritical fluid (SCF), commonly nitrogen (N2) or carbon dioxide (CO2), is used to create millions of micron-sized bubbles in thin wall molded parts. There are a variety of ways to introduce the supercritical fluid into the melt. In one example, shown below, a specially-modified injection molded machine is used to deliver SCF to special injectors, as illustrated in (a) below, and from there into the barrel where it is mixed with the polymer via a specially designed screw, to form a single-phase solution, as illustrated in (b) below. The single-phase solution is maintained using a shut-off nozzle and the back-pressure from the injection screw.

Microcellular injection molding process

.a) SCF is injected into the barrel/melt through the control valves. b) gas is dissolved in polymer melt to form single-phase solution.

Clamp force requirements are reduced because the supercritical foaming agent acts as a solvent, lowering the viscosity of the material by 40-60%, so less pressure is required to push the material into the mold cavity. The process can be run at temperatures as much as 140°F below normal.

Applications

- Light weight parts for the automotive industry

- Stable parts for the medical industry

- Environmentally-friendly parts for the packaging industry

- Consumer parts

Benefits

- Reduced manufacturing costs

- Shorter cycle times

- Long term stability due to low residual stress

- Reduction in the amount of resin used

- Lighter parts

- Low warpage

- No sink marks

- Lower injection pressures

- Lower temperatures