The hot runners are occupied by one material during molding, therefore, you need to specify which material (A or B) is injected from a particular injection location.

Modeling

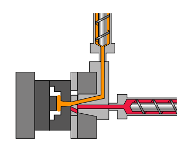

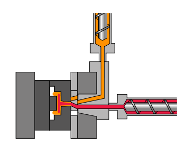

Each hot runner will have a material assigned to it (A/B, or skin/core material). The hot runner that is carrying material A and material B will meet at a cold runner or a part element.

The sequence of steps required for modeling a hot runner for a Co-injection molding analysis is listed below:

- Include the hot runner (gate/sprue) in the design.

- One hot runner system is for material A (skin), and the other hot runner system is for material B (core). The two systems will meet at a cold runner or a part element, depending on how your part is modeled.

- Use Set Co-injection Material in the Analysis menu to assign material A or B to each injection location.

How it works

The Co-injection molding analysis automatically determines the last element in the hot runner (that is connected to the cold runner or the part). It attaches the gate valve property to those elements and closes or opens the valve as the material switches from A (skin) to B (core) or B to A.

The analysis log generated during the analysis will show the valve gates opening or closing as the material switches.