This result provides the source term in the temperature equation used in the analysis. Look at this result first and determine where the Joule heat is being generated in the mold, and if this is where it is expected.

Obtaining this result

Dual Domain

Dual Domain  3D

3D

- Cool (FEM)

This result does not appear in the Study Tasks pane by default. Instead you can create it as a New Plot, after the analysis has run, by clicking  (). Joule heat is listed in the Available results.

(). Joule heat is listed in the Available results.

Using this result

The induced electric current in the coil gives rise to joule heating within the mold and insert. By carefully selecting the materials in the mold, the induced current can be used to generate heat in targeted areas. Ideally, with correct selection of metals and mold modeling, the insert will be heated to the required temperature, and the mold will remain relatively cool.

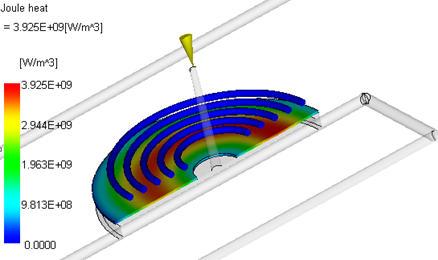

Figure 1 shows an example of the joule heat generated on a nickel insert surface which was placed directly above the part. The material properties of nickel mean it will heat relatively readily under the influence of an induced current.

Figure 1: Joule heat generated on a nickel insert surface

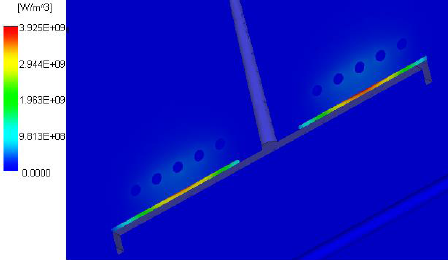

Figure 2 shows the heat generated in the mold/nickel insert combination on a cutting plane for the same model. Since the insert is made from nickel, which is better suited to heat generation more heat is generated in the nickel insert than in the ordinary tool steel used in the mold, especially in the skin depth of the nickel insert relative to the surrounding mold.

Figure 2: Joule heat generated in the mold and insert

Things to look for

- the insert heats up to the required temperature

- the mold remains relatively cool

- take a look at the temperature plot and check the temperature rise caused by the Joule heating. If the pattern and location are as expected, but insufficient, consider raising the current or frequency on the boundary condition

- if the Joule heat distribution does not appear as expected, check if the induced current is occurring in the correct location, check the magnetic field, maybe choose different mold materials or alter the mold geometry.