Autodesk® Nastran® In-CAD software is a general purpose finite element analysis (FEA) tool embedded in Autodesk® Inventor. It is powered by the Autodesk® Nastran® solver, and offers simulation capabilities that span across multiple analysis types, such as linear and nonlinear stress, dynamics, and heat transfer.

Autodesk® Nastran® In-CAD is available as a network license and serves multiple CAD platforms to provide a consistent user experience and eliminate the need for multiple single-platform simulation technologies. It delivers high-end simulation technology in a CAD-embedded workflow so you can make great products.

In this topic, we present a brief overview of the Basic and Advanced analysis types available in Autodesk® Nastran® In-CAD.

Basic Analysis Capabilities

|

Analysis Type |

Example |

Description |

|---|---|---|

|

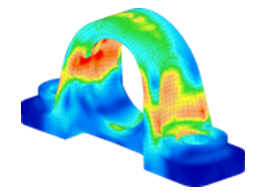

Linear Statics |

|

Linear statics is one of the most common types of analysis. Determine stress, strain, and deformation resulting from applied static loads and imposed constraints.

Linear statics is the easiest and most common class of FEA. It provides the capability to simulate static loads and slowly applied loads. |

|

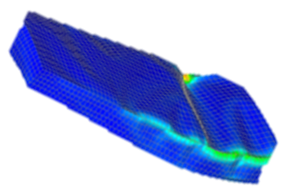

Buckling |

|

Use buckling to assess the stability of a device under loads. Buckling examines structures for sudden failure modes caused by compressive forces.

Linear buckling is computed with Euler buckling formula. Use nonlinear buckling to simulate large deformations, contact and nonlinear material behavior in calculation of buckling load. |

|

Prestress Static and Normal Modes |

|

Use prestress static and normal modes to analyze structures subjected to initial stress, and model the effect of the initial stress state on the structures' displacements, stresses, and modes. |

|

Normal Modes |

|

Use normal modes to determine the undamped natural mode shapes and frequencies of structures. This allows designer engineers to explore and resolve problems with noise and vibration.

|

|

Linear Steady State Heat Transfer |

|

Analyze heat transfer to determine the temperature distribution using the principles of conduction and convection heat transfer. Compute steady state and time-dependent heat loading using:

You can transfer temperature results to structural analyses as thermal loads. |

|

Composites |

|

Simulate the performance of complex ply data. Analysis based on latest failure indices, including Puck and LaRC02.

|

|

Assembly Modeling with Contact |

|

Go beyond analyzing individual parts. Real world simulation of assemblies is possible with sophisticated modeling of different kinds of contact interactions including sliding, friction and welded contact types. |

|

Thermal Stress |

|

Analyze structures subjected to thermal loads. |

Advanced Analysis Capabilities

|

Analysis Type |

Example |

Description |

|---|---|---|

|

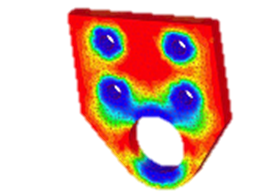

Nonlinear Statics |

|

Nonlinear statics provides the ability to add more realistic simulation with contacting parts, nonlinear elastic and plastic materials, and large deformations. Computes advanced nonlinear solutions such as large displacements/rotation, large strain, plasticity, hyperelasticity, creep etc. |

|

Nonlinear Transient Heat Transfer |

|

Simulate heat transfer with nonlinear linear thermal boundary conditions that vary through time. An example is transient heat generation caused by power fluctuations.

|

|

Nonlinear Steady State Heat Transfer |

|

Simulate heat transfer with nonlinear thermal boundary conditions such as temperature dependent thermal properties. |

|

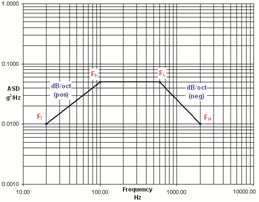

Random Response |

|

Analyze structural behavior in response to random dynamic loads. |

|

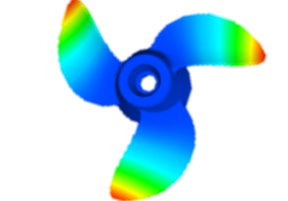

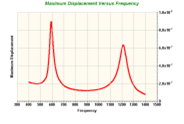

Frequency Response |

|

Dynamic solutions add the ability to include time and mass in the solution. Capabilities include:

Use frequency response to determine the structural harmonic response based upon frequency-dependent loads. |

|

Linear and Nonlinear Transient Response |

|

Simulate the time-dependent response of a structure under the influence of constant or time-dependent loads. An example is impulse loading. |

|

Advanced Nonlinear and Hyperelastic Materials |

|

Simulate complex nonlinear phenomena such as plasticity, hyperelasticity, and shape-memory effect. This enables the analysis of a wide range of materials, from metals and shape-memory alloys to rubbers and soft tissue. |

|

Automated Impact Analysis (AIA) and Drop Test |

|

Simulate drop tests and other impact type loadings easily and automatically. Define impacting parts, path, and velocity. Define initial conditions and loads, and run as a nonlinear transient analysis. Sophisticated treatment provides realistic and meaningful impact and drop test simulations. The only inputs required are projectile velocity and acceleration. |

In addition to these listed analysis types, you can use Autodesk® Nastran® In-CAD to conduct Fatigue, Vibration Fatigue, and Response Spectrum analyses.

This video tells the Autodesk Nastran In-CAD Story.

|

Previous Topic: About Self-Paced Training |

Next Topic: The Basics of Finite Element Analysis (FEA) |