Now we will add a pin-joint between the holes of the two parts. The parts will rotate about the center of the holes.

- Click the Top face of the ViewCube and ensure that the view is in the rotational position shown below step 2. If necessary, click one of the rotation arrows above or to the right of the ViewCube to rotate the view to the upright position (the rotation arrows only appear while the cursor is on or near the ViewCube).

- Click

View

View  Navigate

Navigate  Zoom

Zoom  Window.

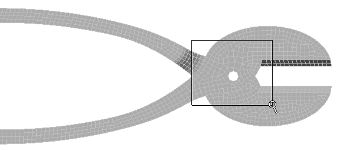

Window. - Draw a rectangle around the hole as shown in the following image to zoom into the fulcrum area. You can also access the

Zoom Window command from the zoom fly-out menu on the Navigation Bar, if preferred.

Zoom Window command from the zoom fly-out menu on the Navigation Bar, if preferred.

- Press the ESC key to quit the Zoom Window command.

Note: Alternatively, you can scroll the mouse wheel with the cursor at the hole to zoom into the fulcrum area.

scroll the mouse wheel with the cursor at the hole to zoom into the fulcrum area. - Draw a rectangle around the hole as shown in the following image to zoom into the fulcrum area. You can also access the

- With the

Selection

Selection  Shape

Shape  Circle and

Circle and  Selection

Selection  Select

Select  Surfaces commands active, draw a circle enclosing the hole. Click first at the center of the circular selection area. The second click indicates the radius of the selection circle. You can also click, drag, and release the button to define the selection area. You are selecting two surfaces, one cylindrical surface for each of two parts.

Surfaces commands active, draw a circle enclosing the hole. Click first at the center of the circular selection area. The second click indicates the radius of the selection circle. You can also click, drag, and release the button to define the selection area. You are selecting two surfaces, one cylindrical surface for each of two parts. - Click

Mesh

Mesh  CAD Additions

CAD Additions  Joint and then click OK to create the joint. The default type is Pin Joint (lines to axis endpoints). Lines from each vertex on the selected surfaces will converge at two endpoints along the centerline of the selected holes. Alternatively, a Universal Joint (lines to axis midpoint) can be created where appropriate (for example, to model a ball-joint connection). A universal joint is not appropriate for this model.

Joint and then click OK to create the joint. The default type is Pin Joint (lines to axis endpoints). Lines from each vertex on the selected surfaces will converge at two endpoints along the centerline of the selected holes. Alternatively, a Universal Joint (lines to axis midpoint) can be created where appropriate (for example, to model a ball-joint connection). A universal joint is not appropriate for this model. - Click the heading for Part 3 in the browser to select the joint and make it more visible.

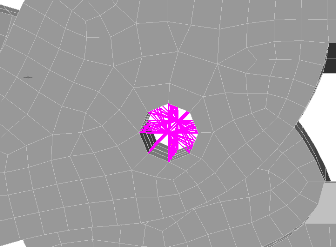

- Click the middle mouse button and drag to slightly rotate the model and inspect the joint. It appears as shown below:

- Click the middle mouse button and drag to slightly rotate the model and inspect the joint. It appears as shown below:

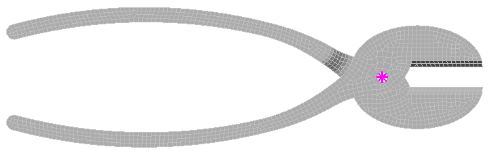

- Click the Top face of the ViewCube. The model appears as shown in the following image.

- Click

Save in the Quick Access Toolbar (QAT) to save your model.

Save in the Quick Access Toolbar (QAT) to save your model.

Note:

- Since Truss elements are used by default when creating joints, the parts are free to rotate (relative to each other) about the axis of the pin joint. Trusses only support axial loads and act as if each end were a frictionless ball-joint. When you need a torsionally rigid joint, change the element type to Beam.

- Even though the default mesh type is Solid, only the surface mesh has been created at this point. By default, the generation of the interior mesh lines is postponed until the first time the Run Simulation or Check Model command is executed.

This tutorial is now complete. You can use the meshed model to complete the Vice Grips Static Stress Analysis tutorial.