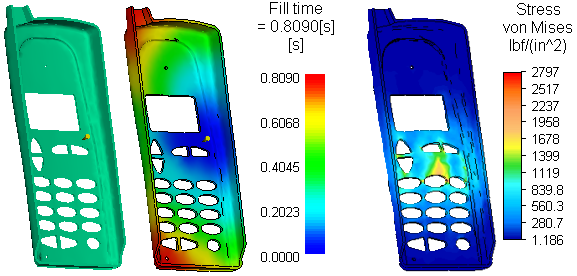

Autodesk Moldflow provides easy-to-use tools that simulates the injection molding process, which allows the user to optimize the part, mold, and tool designs long before manufacturing begins. By using a digital prototype to simulate the injection molding process, you can reduce the number of physical prototypes required to perfect a design and get your products to market faster.

Because injection molding can result in materials that are anisotropic in nature (different properties in different directions) and with varying orientation of the fibers throughout the part, performing a Moldflow analysis and incorporating the results in the Simulation Mechanical stress analysis will provide a more accurate simulation.

Limitations

The following items are not considered in the Simulation Mechanical analysis when using results from Moldflow:

- Residual stress from Moldflow Adviser analyses. The parts are assumed to start with 0 initial stress. Moldflow Insight results, however, do provide residual stresses.

- Nonlinear material properties. The material is assumed to be elastic.

- In Mechanical Event Simulation, small strains are assumed; that is, the direction of the material axes is not updated throughout the analysis due to the deformation (strain) of the elements. The material directions are updated based on rigid body motion.

How to Use Moldflow Results in Simulation Mechanical

There are two workflows outlined herein, depending upon whether or not the Moldflow analysis has already been setup and run at the time the Simulation Mechanical model is started. The following restrictions apply regardless of which workflow you choose:

- Each part within a Moldflow model must consist of a single contiguous volume. Multiple parts (assemblies) are allowed as long as each individual part consists of a single volume. Though Simulation Mechanical and many CAD applications allow a part to consist of multiple volumes, this practice must be avoided to ensure interoperability with Moldflow.

- Avoid using symmetry models. Although this technique is commonly used for stress analysis, the injection molding process is rarely symmetrical in nature.

- You must use one of the following supported element types for the Simulation Mechanical plastic parts (that is, the parts to which the Moldflow material model and Moldflow results are applicable):

Analysis Type Brick elements Tetrahedral elements Linear yes no MES/Nonlinear yes yes

Procedure 1: The Moldflow results are available before the Simulation Mechanical model is started.

Prerequisites:

- The Moldflow model has already been set up and analyzed. The Moldflow study file (*.sdy) is available from the Simulation Mechanical workstation (either copied locally or from a shared network drive).

- The original CAD solid model on which the Moldflow model was based is available on the Simulation Mechanical workstation (copied locally). Note: While storing your models on a local hard disk is not mandatory, we recommended that you work from a local drive to limit network traffic and to improve performance.

In Simulation Mechanical:

- Open the same CAD solid model from which the Moldflow model was derived.

- Mesh the model. The element type will automatically be set to Brick for all solid parts.

- For each injection molded plastic part in the assembly:

- Edit the Element Definition. From the Material model drop-down menu, choose Moldflow, adjust any other settings as desired, and click OK.

- Edit the Material. Choose the appropriate material from the Autodesk Simulation Plastics Library and click OK. Note: The homogeneous isotropic properties from the library are shown. The analysis will get the actual anisotropic properties from Moldflow.

- From the Application Menu (

), click Moldflow Study Manager. Note: The Moldflow Study Manager command will not be available in the Application Menu until the material model has been set to Moldflow for at least one part.

), click Moldflow Study Manager. Note: The Moldflow Study Manager command will not be available in the Application Menu until the material model has been set to Moldflow for at least one part. - Click in the Associated Moldflow Study File column for one of the listed plastic parts. An ellipsis button (...) will appear at the right end of the data field.

- Click the ellipsis button (...). A Browse for Moldflow Study File dialog box appears.

- Navigate to the associated Moldflow study file (*.sdy) and select it.

- Click Open.

- Repeat step 5 for any additional injection molded plastic parts in the assembly. Then, click OK to close the Autodesk Moldflow Study Manager.

- Complete the model set up (loads, constraints, analysis parameters, and so on) and run the simulation. The results will reflect the effects of the Moldflow anisotropic material properties.

Procedure 2: The Simulation Mechanical model is started before the Moldflow model has been set up and analyzed.

In Simulation Mechanical:

- Create the model as usual - mesh, loads, boundary conditions, and so forth.

- For parts that correspond to the plastic part(s) to be analyzed in Moldflow, set the Element Definition: Material Model to Moldflow. This is an anisotropic material model.

- Select a material as usual. When the material model is set to Moldflow, the library will automatically show the Autodesk Simulation Plastics Library. A different library cannot be chosen, and a custom material cannot be entered. Note: The homogeneous isotropic properties from the library are shown. The analysis will get the actual anisotropic properties from Moldflow.

- Perform an Analysis

Analysis

Analysis  Check Model.

Check Model. - Export the model to Moldflow using

Export

Export  Moldflow Adviser or Moldflow Insight. This will display a Browse For Folder dialog; select a folder where the Moldflow project will be created. Each Moldflow part in the Autodesk Simulation will create a different Moldflow study within the Moldflow project. Optionally, activate the Start Autodesk Moldflow after exporting checkbox if ready to run Moldflow. Note:

Moldflow Adviser or Moldflow Insight. This will display a Browse For Folder dialog; select a folder where the Moldflow project will be created. Each Moldflow part in the Autodesk Simulation will create a different Moldflow study within the Moldflow project. Optionally, activate the Start Autodesk Moldflow after exporting checkbox if ready to run Moldflow. Note:- Autodesk Moldflow Insight performs various analyses, including both residual stress and coefficient of thermal expansion (CTE).

- Autodesk Moldflow Adviser performs a subset of the analyses available with Moldflow Insight. Adviser also supports CTE, but does not support residual stress.

The Moldflow project is located in a folder underneath the user-selected folder. The folder and project names default to name of the Autodesk Simulation model. The default name for each study is the Autodesk Simulation part number and part name. Spaces, dashes, and other special characters in the names are changed to underscores (_) in the Moldflow name.

In Autodesk Moldflow:

- If Moldflow was not started when the model was exported from Simulation Mechanical, start Moldflow.

- Open the project and make any changes as desired to the setup. Then, perform a Fill+Pack analysis on each study (each part from Simulation Mechanical). Refer to the Moldflow help documentation for instructions.

- Review the results, as usual.

In Simulation Mechanical:

- If any Moldflow results are in a study different than the one to which the Autodesk Simulation model was exported, browse for the location:

- Click

Moldflow Study Manager.

Moldflow Study Manager. - Click the cell showing the Associated Moldflow Study File for the part .

- Click the

browse button.

browse button. - Select the appropriate file and click Open.

- Click OK to close the Study Manager.

- Click

- Start the analysis (Analysis

Analysis

Analysis  Run Simulation). If the material was changed in Moldflow, the new material will show in Simulation Mechanical after the stress analysis is performed.

Run Simulation). If the material was changed in Moldflow, the new material will show in Simulation Mechanical after the stress analysis is performed. - Review the results, as usual. Note that results related to the Moldflow analysis, including the orientation of the fibers, must be viewed in Moldflow.

Hints and Tips

- Moldflow generates its own mesh based on the outside surface mesh from the part in Autodesk Simulation Mechanical. Therefore, all curved surfaces are approximated as faceted faces - the finer the mesh, the more accurate the approximation of the curved surface. This may affect how fine you make the mesh density to satisfy the needs of the injection model.

- Once the Moldflow results are computed, the Simulation Mechanical model can be analyzed multiple times to test different boundary conditions, loads, and so on. In theory, the mesh can be changed in Simulation Mechanical without needing to export the revised model to Moldflow. The only time that the model needs to be exported to Moldflow is if the position or shape of the plastic parts change.

- Moldflow does not need to be installed on the same computer as Simulation Mechanical. The user can export the model to the local computer, copy the exported project files to a computer with Moldflow, run the Moldflow analysis, and copy the project files (and results) back to the Simulation Mechanical computer.

- Remember that the material properties shown in Autodesk Simulation, when selecting or modifying the materials for each part, and the properties in the Report are generalized isotropic properties. Use these as a reference only. The actual material properties - which may be different at each element - are derived from the Moldflow analysis.

If the stress model is archived (see the page Open or Export Model Files: Archives), keep in mind that the Moldflow results are in a separate model and therefore are not included in the stress model archive. The Moldflow results should be exported to a ZIP archive separately.