Bolts, screws, rivets, and other types of fasteners appear in many designs. Depending on the level of detail needed in the area of the connection, these types of connections can be treated in one of the following manners. (Recall that the FEA model is usually an idealization of the real world, so details in the fastener may not be necessary.)

- Ignore the fastener itself and assume the parts are bonded together in the area of the connection. The loads are transmitted between the parts through a full-strength connection. Regions of the model remote from the connection will give accurate results. The results at the fasteners should not be used (except for providing results to use in a hand calculation of the fastener).

- Model the fastener as a beam or truss element along the centerline of the holes in the parts. The fastener is bonded on each end to the nodes of the hole, so slippage is assumed to not occur in the analysis. The results are reasonable in all areas of the model, given the approximation of the fastener to part interaction.

- Model the fastener with brick elements. The contact between the fastener and connected parts can either be bonded (no slippage), or contact between the parts can be included. These results are the most realistic that can be obtained at the expense of a much more complex model and longer runtime.

This page describes the beam element approach. For simplicity, the type of fastener will be called a bolt although the approach can represent any type of similar fastener. For CAD models, the Generate Bolted Connection wizard automates many of the steps necessary to create and load the geometry of a fastener. To create a bolt, use Mesh  CAD Additions

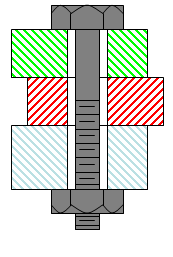

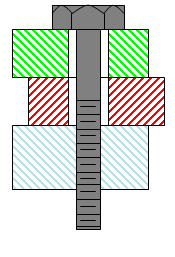

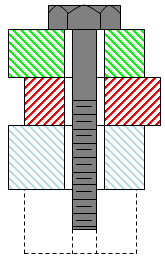

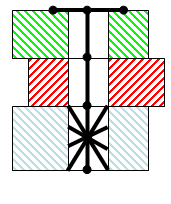

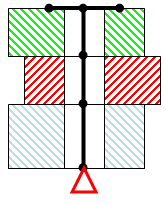

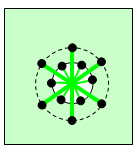

CAD Additions  Bolt. Three types of bolts can be created as shown in the following figures. The top row of figures shows the physical joint; the bottom row shows the FEA equivalent, where the heavy lines are beam elements created by the bolt wizard.

Bolt. Three types of bolts can be created as shown in the following figures. The top row of figures shows the physical joint; the bottom row shows the FEA equivalent, where the heavy lines are beam elements created by the bolt wizard.

|

|

|

|

|

|

| Bolt With Nut |

Bolt Without Nut The bolt is threaded (tight fit) into the bottom part (extra bolt elements connect the shank to the hole). |

Grounded Bolt The bolt is threaded into the foundation or other rigid item that is not modeled. A boundary condition is placed on the end of the bolt. |

Create bolts in a CAD model

The bolt wizard creates beam elements along the centerline of the hole to represent the shank of the bolt. Additional beam elements connect the head (and nut if applicable) of the bolt to the nodes around the perimeter of the hole. Here's how to create the bolt:

- Optionally, mesh the CAD solid model. Any previously defined bolts will be re-created to fit the new surface mesh. (Meshing the model will delete all of the lines associated with all of the parts associated with bolts.)

- Defines each bolt, one at a time, using Mesh

CAD Additions

CAD Additions  Bolt. Although the bolts can be defined after generating a surface mesh, it is more efficient to define the bolts before creating the mesh. See the description below for an explanation of each input.

Bolt. Although the bolts can be defined after generating a surface mesh, it is more efficient to define the bolts before creating the mesh. See the description below for an explanation of each input. - When the OK button is clicked on the Generate Bolted Connection dialog box, the following steps occur automatically:

- Determine the axis of the hole from the selected interior hole surfaces. (The centerline is determined from the average coordinate of the nodes on the perimeter of the hole; thus, a non-uniform mesh can lead to the bolt centerline being offset from the true centerline.)

- Draw a line along the axis of the hole, starting from where it meets the bolt head contact surface and ending where it meets the opposite faces. This line will be referred to as the bolt line.

- Divide the bolt line into segments, one segment for each part bolted together.

- Draw lines from the head end of the bolt line to each node on the perimeter of the head end hole. (This step is done only if the model is already meshed.)

- If the head diameter is larger than the hole diameter, determine where the ends of each head spoke will be based on the user input head diameter and number of spokes. Seed points will be created at these locations. (If the head diameter is smaller than the hole, then no head spokes or seed points will be created.)

- Create lines from the end of the bolt line at the head end to each seed point.

- For a bolt with a nut, and if the nut diameter is larger than the hole diameter, seed points will be created at the locations of the ends of the spokes. (If the nut diameter is smaller than the hole, then no nut spokes or seed points will be created.)

- For a bolt with a nut, draw lines from the nut end of the bolt line to each node on the perimeter of the nut end hole. (This step is done only if the model is already meshed.)

- For a grounded bolt, the end of the bolt line opposite from the bolt head surface will be fully constrained. (If the model is not yet meshed, the boundary condition will appear when the model is meshed.)

- For each set of surfaces that has been specified as a tight fit, do the following:

- Split the appropriate bolt line segment at the midpoint.

- Draw lines from the midpoint to each node on the surface of the hole on that part. (This step is done only if the model is already meshed.)

- An entry is added under Meshes in the browser (such as Bolt without Nut Mesh 1 ). You can conveniently edit the bolt parameters using the context menu accessed by right-clicking on the listed bolt mesh heading.

- If the bolt’s assigned part number does not exist, it is created with the element type assigned as Beam. Additionally, the new part is assigned the same name as that listed under Meshes for this bolt. You can rename the part if desired.

- The Element Definition will be filled in automatically using a round cross section with properties equal to the bolt diameter. Note that this dictates that the last bolt created will set the diameter for all bolts in the same part.

- Apply the bolt preload to all segments of the bolt line.

- If any bolts have head or nut spokes and the model is already meshed, then you must remesh the model to connect the surface mesh to the spokes.

The input on the Mesh  CAD Additions

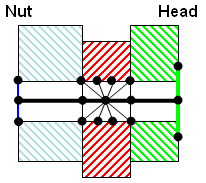

CAD Additions  Bolt command is as follows. Each type of bolted connection uses similar input. Unless indicated otherwise, the following input is used for each of the three types. Refer to the following table for bolt nomenclature.

Bolt command is as follows. Each type of bolted connection uses similar input. Unless indicated otherwise, the following input is used for each of the three types. Refer to the following table for bolt nomenclature.

|

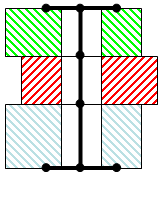

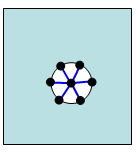

|

|

| View of Nut Side. The nut diameter is smaller than the bolt, so there are no nut spokes. The nut consists of the lines that connect the bolt line to the perimeter of the hole (thin blue lines). | Side View of bolt. The bolt line is the heavy black line on the centerline of the hole. The middle section is set as a tight fit, so the nodes on the surface of the hole are connected to the center of that bolt segment (thin black lines). | View of Head Side. The head diameter is larger than the bolt, so six spokes (heavy green lines) are added based on the head diameter (dashed circle). The thin green lines connect the bolt line to the perimeter of the hole. |

- Part Number: Specify the part number for the bolt. This must be a new part number or an existing beam element part. If more than one bolt is assigned to the same part number, the cross sectional properties of the bolt are based on the last bolt entered or modified.

- Type of Bolt: Choose the type of bolt from the drop-down list. (See Figure 1.)

- Bolt diameter: Enter the diameter of the bolt shank. The cross sectional properties of the beam elements will use this diameter. (The radial spokes for the bolt head, nut, and tight fit lines will also use this diameter.)

- Number of spokes: This entry controls the number of spokes that represents the head or nut. These lines are created with a radius of half the head or nut diameter. This helps to distribute the load of the bolt to a larger area and prevents stress concentrations. Note that these spokes are in addition to the lines that connect the bolt line to the perimeter of the hole.

- Bolt head: Contact surfaces: This box lists the surfaces that the bolt head contacts. Select the appropriate surface or surfaces (Selection

Select

Select  Surfaces) and click the Add button to add them to the list.

Surfaces) and click the Add button to add them to the list. - Head diameter: Enter the diameter of the head. This controls the length of the head spokes that will be created. If the head diameter is smaller than the bolt diameter, then no head spokes will be created.

- Interior hole surfaces: This box lists the surfaces of the hole. Select the appropriate surface or surfaces (Selection

Select

Select  Surfaces) and click the Add button to add them to the list. (The Selection

Surfaces) and click the Add button to add them to the list. (The Selection  Shape

Shape  Circle command is handy for this step.) Keep in mind that only one bolt can be created at a time. Each of the listed surfaces includes a Tight Fit check box. If the check box is activated, the section of bolt will be connected to each node on the surface of the hole. That is, there is no clearance between the bolt line and the hole.

Circle command is handy for this step.) Keep in mind that only one bolt can be created at a time. Each of the listed surfaces includes a Tight Fit check box. If the check box is activated, the section of bolt will be connected to each node on the surface of the hole. That is, there is no clearance between the bolt line and the hole. - Nut: Contact surfaces: For bolt types with a nut, this box lists the surfaces that the nut contacts. Select the appropriate surface or surfaces (Selection

Select

Select  Surfaces) and click the Add button to add them to the list.

Surfaces) and click the Add button to add them to the list. - Nut diameter: For bolt types with a nut, enter the diameter of the nut. This controls the length of the nut spokes that will be created. If the nut diameter is smaller than the bolt diameter, then no nut spokes will be created.

- Preload magnitude: To preload the joint, select either Axial Force or Torque. If a torque is entered, it is converted to an axial force based on one of these equations when the bolt is created:

With a nut:

Without a nut:

where T is the torque magnitude, K is the Torque coefficient, and D is the bolt diameter. For additional details on how the preload is applied to the elements, see the Beam Preloads page.

Note:- Preloads are only available if the bolts are analyzed as beam elements, and only in Static Stress with Linear Material Models, Mechanical Event Simulation, and Static Stress with Nonlinear Material Models.

- For a real bolted connection, the bolt preload creates forces in the bolt and the members. In FEA, the beam element has an initial force but the members have 0 force. Since the structure is not infinitely stiff, one result of a preload is that the structure deforms and relieves a portion of the preload. If the bolt preload is critical in the design, it may be necessary to run the analysis with no external loads to check how much preload is lost.

- Remove button: If a wrong surface is added to the bolt head, interior hole, or nut surface, select the entry in the list box. The corresponding surface is highlighted on the model. Then use the appropriate Remove button. Using standard Windows techniques, use the Shift key in conjunction with the left mouse button to select a range of surface entries in the list box, and use the Ctrl key to toggle a single selection on and off.

If multiple bolts need to be created, and especially if the bolt heads and nuts contact the same surfaces, use the Do not dismiss dialog after bolt generation option to keep the dialog open. When used, all of the input except for the Interior hole surfaces will be retained. You can quickly specify the new interior hole surfaces for each bolt. For example, to generate three bolts connecting the same plates together, the general steps would be as follows:

- Start the bolt wizard from Mesh

CAD Additions

CAD Additions  Bolt.

Bolt. - Enter all of the input for the first bolt.

- Activate the check box Do not dismiss dialog after bolt generation.

- Click the OK button. The first bolt is created and the interior hole surface input is cleared. All other input is retained.

- Add the surfaces for the interior hole surfaces of the second hole.

- Activate the check box Do not dismiss dialog after bolt generation.

- Click the OK button. The second bolt is created and the interior hole surface input is cleared.

- Add the surfaces for the interior hole surfaces of the third hole.

- Click the OK button. The third bolt is created and the dialog is closed.

- Mesh the model if needed.

Modifying Bolts in a CAD Model

Previously defined bolts can be modified or deleted by selecting the bolt in the Meshes branch of the tree view, clicking the right mouse button, and choosing the desired command.

You can also modify the lines generated by the bolt wizard using any of the standard mesh construction techniques, such as adding lines, point move, dividing lines, intersecting, and so on. This method is not recommended because re-meshing the model will recreate the bolts, so manual modifications may be overwritten, or overlapping elements may occur.