View a comparison of the progressive failure model used in Helius PFA and the progressive damage model used by Abaqus.

For composite materials, Abaqus provides a progressive damage model that uses the Hashin criteria to predict the initiation of four different constituent failure modes and uses damage evolution equations to predict the post-initiation stiffness degradation that results from the evolution of each of the four constituent damage modes. This section provides a comparison between the instantaneous progressive failure model used in Helius PFA and the progressive damage model provided by Abaqus.

There are several fundamental differences between the instantaneous progressive failure model used in Helius PFA and the progressive damage model provided by Abaqus. These differences are discussed below.

- In the Abaqus progressive damage model, the material stiffness is gradually reduced as deformation continues to accumulate after the initiation criterion is met. In contrast, Helius PFA imposes an instantaneous stiffness reduction determined by the particular constituent that failed. This type of instantaneous, discrete stiffness reduction normally poses severe convergence difficulties for finite element codes. However, Helius PFA is specifically developed to efficiently handle this type of behavior and exhibits very robust convergence behavior.

- In the Abaqus progressive damage model, damage initiation and damage evolution of the material constituents (fiber and matrix) are predicted based on the composite average states of stress and strain. In contrast, the MCT criteria in Helius PFA uses the constituent average stress states to predict failure in each of the individual material constituents.

- The Abaqus progressive damage model predicts damage initiation and damage evolution based solely on the in-plane stress and strain components, ignoring the contribution of the transverse stress and strain components. In contrast, MCT predicts constituent failure using the full 3-D constituent average stress state.

- As damage evolves, the Abaqus progressive damage model only accounts for stiffness reduction in the in-plane stiffnesses (E11, E22, G12), leaving the transverse stiffnesses (E33, G13, G23) unchanged. In contrast, as material constituent failure occurs, Helius PFA explicitly accounts for stiffness reduction in both the in-plane and transverse stiffnesses.

- The Abaqus progressive damage model can only be used in conjunction with 2-D continuum elements and shell elements. Helius PFA can be used in conjunction with 2-D continuum elements, shell elements, and 3-D continuum elements.

In this section, the Abaqus progressive damage model and Helius PFA are each used to simulate the failure response of the composite conic structure. Due to the differences listed earlier in items 4 and 5 above, continuum shell elements (SC8R) are used in both models. This choice eliminates the differences listed in items 4 and 5. Consequently, any differences in the predicted failure response of the structure are due entirely to the differences listed in items 1-3 above.

In addition to the fundamental mathematical differences listed above, the Abaqus progressive damage model poses additional difficulty to you in that it is rather difficult and confusing to define. The process of defining the Abaqus damage initiation (Hashin) criteria is straightforward and requires only industry standard strength measurements:

- Longitudinal tensile and compressive lamina strength (+S11 and -S11)

- Transverse tensile and compressive lamina strength (+S22 and -S22)

- Longitudinal and transverse shear strength of the lamina (S12 and S23)

However, the process of defining the Abaqus damage evolution relationships is difficult and confusing. The four parameters required for the damage evolution relationships represent the amount of energy that is dissipated in each of the four constituent failure modes:

- Energy dissipated during damage for fiber tension (Gcft)

- Energy dissipated during damage for fiber compression (Gcfc)

- Energy dissipated during damage for matrix tension (Gcmt)

- Energy dissipated during damage for matrix compression (Gcmc)

These energy dissipation constants are not readily available for most unidirectional composites (including AS4-3501-6). Furthermore, the convergence performance of the Abaqus finite element code is very sensitive to the numerical values chosen for these energy dissipation constants. Therefore, even if you have access to experimentally measured energy dissipation values, it is likely that you will have to adjust these values in an effort to improve the convergence behavior of the finite element solution. In contrast, Helius PFA does not require these energy dissipation values and it actually improves the convergence behavior of the finite element solution rather than degrading the convergence behavior.

The progressive failure response of the composite conic structure was simulated using different models (listed below). Both models were identical except for the failure criteria that were employed. The EP1_SC8R.inp model used MCT to predict constituent material failure and stiffness reduction, and the EP1_Hashin.inp model used the Abaqus progressive damage model to predict constituent material failure and stiffness reduction.

Models

EP1_SC8R.inp

- Failure criteria: MCT

- Element type: SC8R

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

EP1_Hashin.inp

- Failure criteria: Hashin

- Element type: SC8R

- Through-thickness mesh density:

- Composite Facesheets: 2 elements

- Foam Core: 4 elements

Results

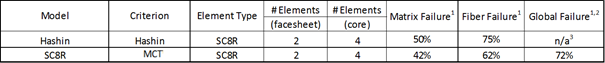

For this particular example problem, a converged solution could not be obtained using the Abaqus progressive damage model after the first localized matrix failure occurred. Consequently, the results reported here do not include a global structural failure load predicted with the Abaqus progressive damage model. The table below shows the load level at which each type of failure event is predicted using the two different progressive failure models. Recall that a converged solution could not be achieved using a progressive damage model after local matrix failure. By turning off the *DAMAGE EVOLUTION capability of the Abaqus progressive damage model and using the Hashin criterion to flag matrix and fiber failure without reducing the material stiffness after local failure, it is possible to determine approximately when fiber failure would occur. This value is approximate because a reduction in the material stiffness due to local matrix failure may cause fiber failure to initiate sooner.

- Load percentage is on a 0-100% scale

- Global failure is defined as a large discontinuity in the load-vertical displacement curve for the 0° application point of the load head shown previously

- Global failure is unable to be determined, see text for details

As seen above, the Hashin criterion predicts that localized matrix failure occurs at a higher load level (50%) than predicted by MCT (42%). This difference is due entirely to the differences in the matrix constituent failure criteria used by MCT and the Hashin model; e.g., constituent average stress versus composite average stress and the specific functional form of the stress-based failure criteria used in each model.

MCT predicts that the first localized fiber constituent failure occurs at a load level of 62%. However, the Hashin criterion predicts that the first localized fiber constituent failure does not occur until the load level has reached 75%. The large difference in the load at fiber failure initiation is due primarily to two issues. First, MCT uses the fiber average stress state, while the Hashin criterion uses the homogenized composite average stress state. Second, MCT predicts an instantaneous stiffness reduction in conjunction with localized matrix failure. Therefore, load is re-distributed to the fibers much more rapidly than predicted by the Abaqus damage evolution model which uses a gradual stiffness reduction.

MCT predicts that global structure failure occurs at a load level of 72%. Interestingly, the Abaqus damage evolution model did not even predict the initiation of localized fiber failure until a load level of 75%. It should be emphasized that after the initiation of localized matrix failure, a converged solution could no longer be obtained with the Abaqus damage evolution model, thus a global structural failure load could not be determined.