Use a single element model to evaluate the shear stress/strain response of a composite material.

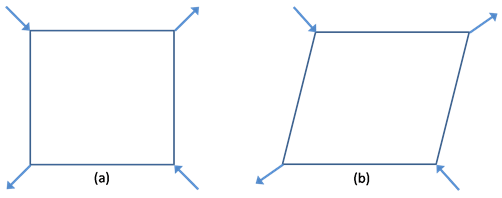

The simplest method of demonstrating the longitudinal shear stress/strain response of a composite material is to constrain and load a single element such that the longitudinal shear stress component is much greater than the remaining stress components. A state of pure shear stress can be obtained by loading an element as shown below.

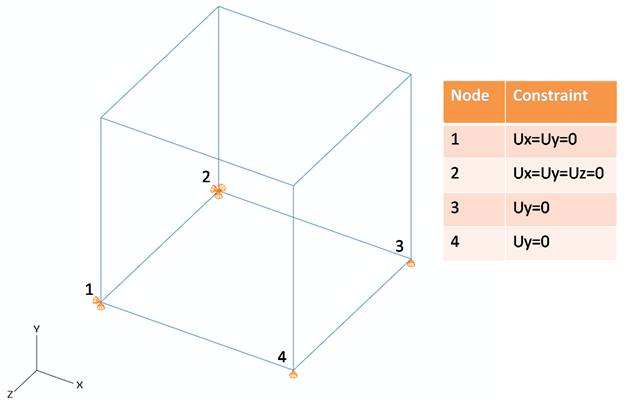

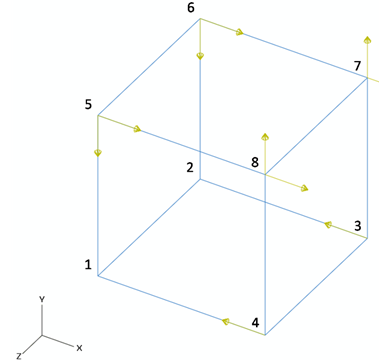

The nodal boundary conditions and loading shown below were used to obtain this loading for the finite element model used in this problem.

The magnitudes of the loads shown above are identical.

The model uses the properties of a SilEglass1200tex-MY750 unidirectional glass/epoxy composite with the fibers oriented in the x-direction. The measured shear strength of the material is 73 MPa. A single 3-dimensional solid element (type C3D8R) was used with 1 integration point.

Based on the given loading, boundary conditions, material, and orientation, the only non-zero composite stress component is σ12.