Add new materials to the material database.

Upon selecting the New Fiber, New Matrix, New Core, or New Lamina option from the New Item drop-down menu, Helius Composite brings up a new material window that is appropriate for the type of new material selected. In either case, you must:

- Specify the name for the new material.

- Specify the in-plane properties and a density of the new material.

- Save the new material in the material database.

- New Fiber, New Matrix, or New Core

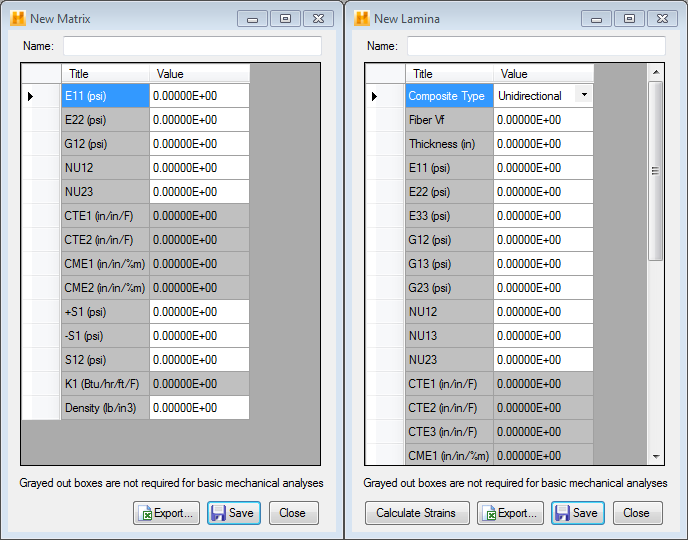

- The left image below shows the New Matrix window which is similar to the New Fiber window and New Core window. These windows differ only in the specific properties available for user specification.

- New Lamina

- The right image below shows the New Lamina window. Unidirectional lamina are assumed to be transversely isotropic, with the properties in the '2' direction being equal to the properties in the '3' direction. The Calculate Strains button located on the window allows you to calculate ultimate lamina strains corresponding to the ultimate strengths of the lamina.

Material Properties

The following list briefly describes the material properties that can be entered into Helius Composite. White fields (as shown above) indicate the minimum properties required; greyed-out boxes are not required for basic mechanical analyses.

- E11

- Effective Young's modulus of the material in the axial 11-direction

- E22

- Effective Young's modulus of the material in the transverse 22-direction

- E33

- Effective Young's modulus of the material in the transverse 33-direction

- G12

- Effective shear modulus of the material in the 12-direction

- G13

- Effective shear modulus of the material in the 13-direction

- G23

- Effective shear modulus of the material in the 23-direction

- NU12

- Poisson ratio interpreted as the free contraction of the material mid-plane in the 2-direction in response to an imposed extension of the material mid-plane in the 1-direction

- NU13

- Poisson ratio interpreted as the free contraction of the material mid-plane in the 3-direction in response to an imposed extension of the material mid-plane in the 1-direction

- NU23

- Poisson ratio interpreted as the free contraction of the material mid-plane in the 3-direction in response to an imposed extension of the material mid-plane in the 2-direction

- CTE1

- Thermal expansion coefficient of the material in the 11-direction. This coefficient governs the free expansion or contraction of the material mid-plane in the 1-direction due to a uniform temperature change.

- CTE2

- Thermal expansion coefficient of the material in the 22-direction. This coefficient governs the free expansion or contraction of the material mid-plane in the global 2-direction due to a uniform temperature change.

- CTE3

- Thermal expansion coefficient of the material in the 33-direction. This coefficient governs the free expansion or contraction of the material mid-plane in the global 3-direction due to a uniform temperature change.

- CME1

- Moisture expansion coefficient of the material in the 11-direction. This coefficient governs the free expansion or contraction of the material mid-plane in the 1-direction due to a uniform moisture change.

- CME2

- Moisture expansion coefficient of the material in the 22-direction. This coefficient governs the free expansion or contraction of the material mid-plane in the global 2-direction due to a uniform moisture change.

- CME3

- Moisture expansion coefficient of the material in the 33-direction. This coefficient governs the free expansion or contraction of the material mid-plane in the global 3-direction due to a uniform moisture change.

- +S1

- Normal tensile strength of the material in the 11-direction.

- -S1

- Normal compressive strength of the material in the 11-direction.

- +S2

- Normal tensile strength of the material in the 22-direction.

- -S2

- Normal compressive strength of the material in the 22-direction.

- S12

- Shear strength of the material in the 12-direction.

- +e1

- Normal strain in the 11-direction caused by uniaxial tensile stress +S1.

- -e1

- Normal strain in the 11-direction caused by uniaxial compressive stress -S1.

- +e2

- Normal strain in the 22-direction caused by uniaxial tensile stress +S2.

- -e2

- Normal strain in the 22-direction caused by uniaxial compressive stress -S2.

- e12

- Shear strain in the 12-direction caused by shear stress S12.

- K1

- Thermal conductivity of the material in the 11-direction.

- K2

- Thermal conductivity of the material in the 22-direction.

- K3

- Thermal conductivity of the material in the 33-direction.

For core materials:

- Ec

- Compressive modulus of the core material

- GcL

- Core shear modulus in the sandwich plate x-direction

- GcW

- Core shear modulus in the sandwich plate y-direction

- DENc

- Density of the core; not the density of the material the core is made from

- dCell

- Honeycomb core cell diameter

- gage

- Honeycomb core cell wall thickness