Compute the transverse deflection of a simply supported sandwich plate under a uniformly distributed transverse load.

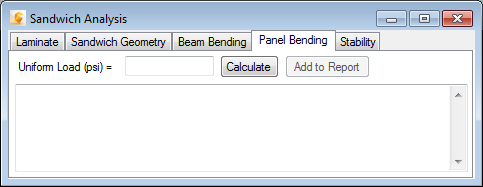

To perform a sandwich panel bending analysis, select the Panel Bending tab from the Sandwich Analysis window. Once the Laminate and Sandwich Geometry have been defined, complete the following steps in the Panel Bending tab (see image below):

- Specify Load - The sandwich panel bending analysis is only performed for a sandwich panel that is simply supported on all four edges and subjected to a uniformly distributed transverse load. Thus, you only have to specify the magnitude (force/area) of the uniformly distributed load.

- Calculate Results - Click the Calculate button to compute the solution. Results are shown in the display window. The printed results consist of the following quantities:

- Panel Data - Length L, Width W, Weight, Pressure Load, Core Type, Core thickness, and Face Sheet thickness.

- Max Deflection - The maximum transverse deflection caused only by bending deformation.

- Face Stress - The maximum in-plane normal stress in the laminated face sheet.

- Core Shear Stress side L - The maximum transverse shear stress induced in the core material along the length.

- Core Shear Stress side W - The maximum transverse shear stress induced in the core material along the width.

- Critical Face Sheet Wrinkling Stress - If the computed Face Stress is greater than the critical stress listed here, the sandwich beam will fail in face wrinkling type buckling.

- Critical Face Sheet Dimpling Stress - If the computed Face Stress is greater than the critical stress listed here, the sandwich beam will fail in face dimpling type buckling. This is applicable for a "honeycomb" core panel only.