Perform a torsion analysis of a laminate tube or beam.

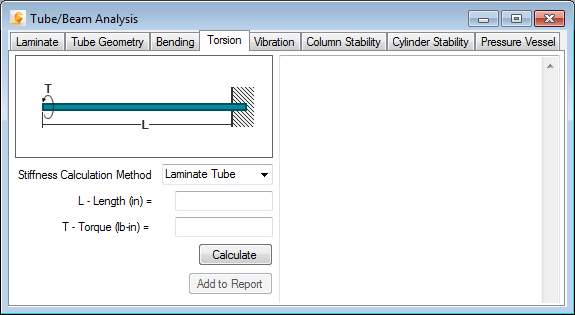

To begin the torsion analysis, select the Torsion tab from the Tube/beam Analysis dialog window (see image below). Torsional results are calculated for a beam which is fixed on one end and is free to rotate, but not warp on the other end. Open cross-section beams are assumed to be "thin walled" and will deflect much more than closed section beams. All algorithms used in this form are taken from Roark's Formulas for Stress and Strain (Ref. 11.1, pp. 345-389, Table 22 Ref. No. 1d.), and the limitations and assumptions listed therein apply here.

- Boundary Conditions and Loading - A pictorial depiction of the boundary conditions and loading is shown in the window. The dimensions and loading required to define the analysis are depicted in the drawing.

- Stiffness Calculation Method - Of particular interest on this form are the "Stiffness Calculation Method" options. These options apply to closed cross-sections only (rectangle, circle, and ellipse).

- The "Ply-By-Ply Tube" option forces all bending analyses to be calculated on a ply-by-ply basis through the thickness of the laminate. That is, the stiffness contribution for each ply is modeled separately.

- The "Laminate Tube" option uses the structural (or smeared) properties of the entire laminate in bending calculations. Whenever you analyze a closed section beam using the "Laminate Tube" option, turn the "Coupling" option under the Laminate tab to zero. This is critical to generating accurate results.

- L - Length - Specify the overall length of the beam.

- T - Torque - Specify the torsional load applied at the free end of the beam.

- Calculate - Once the input has been completed, click Calculate to compute the torsion solution. The output box on the bottom of the window shows the results of the defined analysis:

- CS Area: This is the cross-sectional area of the beam.

- Stiffness GJ: The equivalent torsional stiffness of the beam cross-section.

- Angle of Twist: The amount of twist in the beam over the defined length.

- Avg. Shear Stress: The average shear stress in the beam cross-section. (For closed cross-section tubes).

- Max Bend Stress Due to Warp: The maximum bending stress on the beam due to warping. (For open ended cross-sections).

- Max Warping Rigidity Shear Stress: Warping rigidity shear stress in the beam due to warping. (For open ended cross-sections).

- Max Torsional Rigidity Shear Stress: Torsional rigidity shear stress in the beam. (For open ended cross-sections).

Once you have calculated the average beam stresses, you can compare them to the allowable stresses for the laminate calculated under First Ply Failure Survey or Progressive Failure options under the "Laminate" module.