Occurrence numbers are typically used to simplify the amount of modeling required for a Fill+Pack analysis by specifying the number of times that a given flow path is repeated in a multiple cavity tool.

For example, for a naturally balanced 8–cavity tool, only one part and the feed system must be modeled.

Occurrence numbers are a useful shortcut that can be used to reduce the amount of modeling and analysis time required for models with symmetrical flow paths, especially in multi-cavity models, where only one cavity needs to be modeled and the other identical cavities can be referenced in the analysis by occurrence numbers. Identical flow paths are defined to have symmetrical physical geometries and identical volumes of plastic flowing through them.

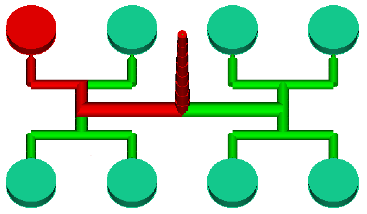

Occurrence numbers in a naturally balanced 8-cavity tool

- The sprue is unique and therefore has an occurrence number of 1.

- The primary runner has an occurrence of 2 because the flow path splits in 2 at the base of the sprue.

- The secondary runners have an occurrence of 4, and the remaining part of the flow path has an occurrence of 8.

Symmetrical Flow Paths

Before you consider modeling simple parts using occurrence numbers, it is helpful to understand the concept of "symmetrical flow paths". Flow paths are said to be symmetrical when the physical geometry of the flow path is symmetrical and when the volume of plastic flowing through the paths are identical.

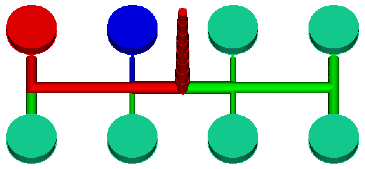

The figure below shows an artificially balanced 8-cavity tool. This runner system contains two distinct flow paths-respectively represented in red and blue-therefore the occurrence numbers differ from the first example.

Occurrence numbers in an artificially balanced 8-cavity tool

- The sprue-in red-is unique and therefore has an occurrence number of 1.

- The primary runner-in red-has an occurrence of 2 because the flow path splits in 2 at the base of the sprue.

- The secondary runners, gates and parts-represented in blue-have an occurrence of 4.

Specifying occurrence numbers

By default, all surfaces and elements in the model are considered to have an occurrence number of 1. Using  (), you can specify an occurrence number other than 1, for example, for a model of a multi-cavity mold. All elements containing the same properties as the selected element will inherit the number, if the Apply to all entities option is selected.

(), you can specify an occurrence number other than 1, for example, for a model of a multi-cavity mold. All elements containing the same properties as the selected element will inherit the number, if the Apply to all entities option is selected.