This section describes the matters raised by the different formats of the inputted geometry within Autodesk Moldflow Insight - Solvers.

- Native CAD formats

- Native CAD formats are the best formats to work with within

Autodesk Moldflow Insight.

Native CAD formats provide information about faces and connections, which leads to surfaces. These pieces of information give much more control on the model than *.iges or *.stl for example and lead to a better and smoother mesh.

However, you must be careful when using a CAD model as these formats often include many defects. Any defect on the CAD model leads to meshing errors and decrease the results accuracy.

The typical defects encountered in CAD formats are:

- No connection between faces;

- Slivers on curved features.

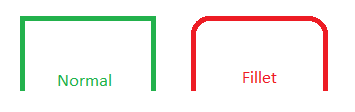

Repair and simplify the CAD geometry before importing it. Use for example Autodesk Moldflow CAD Doctor or Autodesk SimStudio Tools. Pay particular attention to the small features. Delete them if they are useless in an analysis point of view, or reduce and smooth them if you really need to keep them. You may also encounter fillets that lead in an increase of the node density.

You can remove fillets to decrease the element counts, but it is optional.

- IGES formats

-

*.iges format provides information about the faces but nothing concerning connections or bodies. A different and specific mesher is used for *.iges models.

The main goal while meshing an *.iges model is to fulfill a maximum of the Quality standards for Surface Meshes. There are three main parameters to consider when working with *.iges models:

- STL formats

-

The *.stl file format only provides information about triangles but nothing about connections, faces, surfaces, or bodies. The main mesh parameter to use, to optimize your mesh with*.stl files, is the Global Edge Length.

A specific mesher is used in Autodesk Moldflow Insight to mesh *.stl models. However it is not easy to get good quality results, due to the nature of the input.