In two-shot sequential overmolding a first component is molded and then used as a substrate on which a second component is injected.

There are different ways in which two-shot sequential overmolding can be achieved. One example is described here. In this two-shot sequential overmolding process, the first component is injected into the first cavity. Once the first shot has finished, the mold platen rotates and carries the first component to the second shot position, where the second component is molded over the first component. The first component injection and the second component injection occur concurrently. So for each cycle one combined part is being manufactured however the first component remains in the mold for two injection cycles.

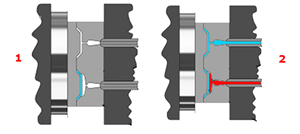

- Following injection, the platen rotates through 180 degrees and the mold closes. The first component (blue) is now present in the lower (overmolding) cavity.

- The first component (blue) and the second component (red) are injected simultaneously.

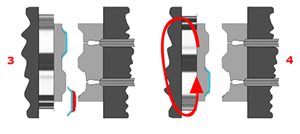

- The mold opens and the completed part is ejected from the lower cavity. The runner for the first component is severed at the same time.

- The platen rotates through 180 degrees and the mold closes. The first component (blue) is now present in the lower (overmolding) cavity.

- The cycle continues.