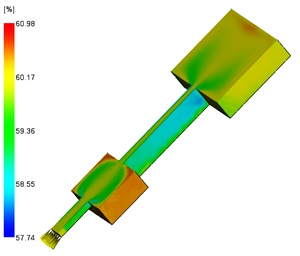

The Powder volume concentration result shows where, in the part, the powder is concentrated, so you can check for non-uniform distribution in the feedstock.

This result is generated from a powder injection molding process.

3D

3D

Mesh type:

Analysis sequences:

- Fill

- Fill+Pack

Using this result

The powder volume concentration result indicates how the powder is distributed throughout the part. This result can be used to anticipate black lines. Black lines are one of the most common defects in powder injection molding. They occur when the distribution of powder and binder in the feedstock is non-uniform, and the powder concentration is comparatively low, but they are not visible until the part has been sintered.

Powder volume concentration result

Things to look for

The result should show uniform color throughout the part. Where there are areas of low powder concentration, consider:

- changing the process settings,

- altering the geometry of the part.