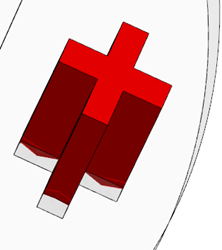

The Re-melt zone, part insert result shows the location(s) where the polymer insert may have melted when the part is injected.

This result is generated at the end of a Fill analysis using 3D analysis technology, where an insert is modeled. The default plot is a shaded plot, which shows the actual remelt zone, where the part insert temperature is above the transition temperature.

Shaded plot

Click

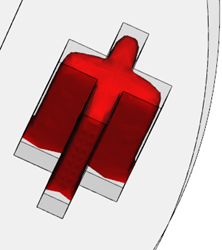

() and change to a contour plot to see the boundary between the remelt zone and the non-remelt zone.

() and change to a contour plot to see the boundary between the remelt zone and the non-remelt zone.

Contour plot

You can control how remelt zones are displayed by editing the plot properties.

Using this result

Remelting occurs when the temperature of the plastic of a polymer insert rises above its transition temperature because of heat transfer from the part. This result tells you where remelting is likely to occur.

Remelting of a thin skin increases structural strength between components. However, it is generally undesirable because it causes unpredictable changes to the properties of the insert, such as its exact shape or optical properties.

Things to look for

- Decrease the injection temperature of the material.

- Change the insert or part material.

- Move the injection location further from the insert.