A study log is generated every time an analysis is performed, consisting of several logs describing different aspects of the analysis. The study log reports on any inputs used, any warnings or errors encountered, and provides a summary of results generated at the end of the filling and packing phases.

The different log tabs you will find in the study log window depend on the analysis sequence you elected to run.

Analysis log

- Header

- This section contains the copyright details of the application. It also lists all of the analyses performed within the sequence, a date and time stamp, and any warnings or errors encountered at the initial stage.

- Summary of analysis inputs

-

All of the inputs specified for the analysis are listed in this section. Use this section to verify that all of the inputs are correct. The following information is described:

- Solver parameters

- Material data

- Process settings

- Model details

- Coolant data for Cool (FEM) analyses

- Cool process settings for Cool (FEM) analyses

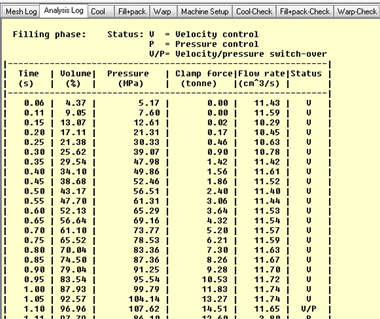

- Analysis progress table

-

This section includes an analysis progress table, which provides tabular results for each time-step in the analysis. During the filling phase you can see the relation of volume of cavity filled, pressure inside the cavity, clamp force, and flow rate to analysis times. During the packing phase the percent of cavity packed over time is reported.

Note: In the case of an Injection-compression analysis, the %Volume value is based on the final cavity thickness when the mold is closed. The %Volume value can therefore exceed 100% before press compression commences. - Results Summary

- Various results are reported in this section of the analysis log, depending upon the analysis sequence chosen. Examples of results reported include the required clamp force and the recommended ram speed profile, bulk temperature, wall shear stress, frozen layer fraction, shear rate, cavity temperature results, and volumetric shrinkage results.

Other logs

In addition to the Analysis log, there are other logs that are created during the analysis, including:

- Mesh log

- Analysis sequence (eg Fill, Fill+Pack, Warp) logs

- Machine setup log

- Analysis sequence check logs