*MATE: Material Property Block

*MATE

*MATI

i1

i2

i1: i*4: Material ID

i2: i*4: Material ID

*????: property card blocks such as *COND, *ELAS, ...

Material properties are defined within blocks starting with the *MATE card and ending when another card other than material property is used. Properties per material ID are defined within each block starting with *MATI followed by an integer (i1, i2, ...) corresponding the Local Simulation auto generated mesh or the material ID used in the PATRAN neutral input file. Internal checks ensure that the necessary properties have been defined by the *MATE card and that they fall within a valid range.

With the inclusion of material properties in the PRM files, it is not necessary to prescribe material properties for the deposition material during part scale simulations. If material properties are included in a part scale input file, they will be superseded by the properties in the input file, as specified by *STLM and *PBPF. Use *MATE in conjunction with *PBS2 to prescribe different properties from the deposition properties to the build plate.

*COND: Thermal Conductivity

*COND

r11, r12

r21, r22

...

r11: r*8: Thermal conductivity value at temperature r12

r21: r*8: Thermal conductivity value at temperature r22

...

This card specifies temperature dependent thermal conductivity.

*DASH: DASHpot Stiffness

*DASH

r11, r12

r21, r22

...

r11: r*8: Spring constant at displacement r12

r21: r*8: Spring constant at displacement r22

...

This card defines displacement dependent stiffness for point elements. This option is useful to model workpieces constrained by non-ridged supports. *DASH is used within the *MATE block.

*DSHP: DaSHpot Pretension

*DSHP

r1

r1: r*8: Pretension of spring

This card allows the definition of pre-tension for a spring defined by the *DASH card. The resulting spring force equals f = k(u)(u – p). Where, f is the spring force, k is the spring stiffness (defined by *DASH), u the displacement, and p is the spring pretension defined by the r1 value in the *DSHP. *DSP is used within the *MATE block.

Required Cards: *DASH

*DENS: Density

*DENS

r1

r1: r*8: Density value

This card specifies temperature independent density in kg/mm3.

*ELAS: Elastic Modulus

*ELAS

r11, r12, r13

r21, r22, r23

...

r11: r*8: Elastic Modulus value at temperature r13

r12: r*8: Poisson's ratio value at temperature r13

r21: r*8: Elastic Modulus value at temperature r23

r22: r*8: Poisson's ratio value at temperature r23

...

This card specifies temperature dependent Elastic Modulus in MPa for temperatures in °C.

*EMIS: Emissivity

*EMIS

r11, r12

r21, r22

...

r11: r*8: Emissivity value at temperature r12

r21: r*8: Emissivity value at temperature r22

This card assigns temperature dependent emissivity to account for heat loss via thermal radiation. For auto generated meshes (using *AUTM), radiation will be applied to all free surfaces. For manually generated meshes (using *INPU), if no surface convection is defined in the Patran input file, no radiation is applied even if the *EMIS card is used.

A convection with zero convection coefficient can be applied on surfaces where there is no surface convection (e.g. in a vacuum).

*EXPA: Thermal Expansion Coefficient

*EXPA

r1

r11, r12

r21, r22

...

r1: r*8: Reference temperature

r11: r*8: Thermal expansion value at temperature r12

r21: r*8: Thermal expansion value at temperature r22

...

This card specifies the temperature dependent thermal linear coefficient of thermal expansion.

*LATE: Latent Heat

*LATE

r1, r2, r3

r1: r*8: Latent heat (energy/volume)

r2: r*8: Solidus temperature

r3: r*8: Liquidus temperature

This option allows for the inclusion of the latent heat of fusion in a thermal analysis. Latent heat is specified as J/kg at Liquidus and Solidus temperatures in °C.

Best Practices: Widening the Solidus to Liquidus temperature range can improve convergence and reduce run times while having minimal effect on the analysis results. It is best to reduce the lower temperature by 100° C and increase the higher temperature by °C to avoid such convergence issues caused by the extreme non-linearity introduced by the inclusion of latent heat in thermal analyses.

*PLAS: Plasticity

*PLAS

i1

r11, r12, r13, r14, ..., r1n,

r21, r22, r23, r24, ..., r2n,

...

n=2*i1+1

i1: i*4: number of (yield strength, equivalent plastic strain) points

r11: r*8: Yield strength for equivalent plastic strain r12 at temperature r1n

...

r13: r*8: Yield strength for equivalent plastic strain r14 at temperature r1n

...

- Isotropic plastic hardening is assumed.

- r12, r22, r32,.. should be zero.

- Perfect plasticity is assumed beyond the last (yield strength, equivalent plastic strain) point.

- If i1=1, the response is elastic-perfectly plastic (no hardening).

Yield strength is input in terms of MPa.

Best Practices: Do not include *PLAS in Part-Scale Powder-Bed Simulations as this behavior is already accounted for in the PRM generation phase and will incur lack of convergence.

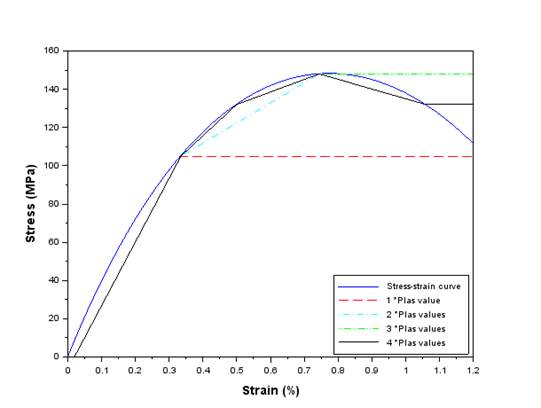

The following graph shows an example of fitting a stress-strain curve using the *PLAS card using 1-4 values. Using just 1 value assumes perfectly plastic behavior. Using 2 points along the stress strain curve will create a bilinear map of plastic properties, one line between the yield point and the second point, and then a region of perfect plasticity extending from the second point. This is the most common method to model the plastic behavior, and has been shown to be effective for various metals. Additional points may be used to further describe the stress-strain curve as desired by the end user. The more detailed the stress-strain behavior is defined in the mechanical model, the slower the convergence will be each step.

Approximating the stress-strain curve using 1-4 values in the *PLAS card

*SPEC: Specific Heat

*SPEC

r11, r12

r21, r22

...

r11: r*8: Specific heat value at temperature r12

r21: r*8: Specific heat value at temperature r22

...

This option assigns temperature dependent specific heat in units of J/kg/oC.

*MLTT: Melting Temperature

*MLTT

r1

r1: r*8: Melting temperature, in oC.

- When the temperature exceeds r1, material melting is simulated.

- If *MLTT is defined outside the *MATE block and the same value is used for all materials.

*SRLX: Stress Relaxation Temperature

*SRLX

r1

r1: r*8: Stress relaxation temperature, in oC

- When the temperature exceeds r1, all elastic, plastic, and thermal stress and strain components are set to zero.

- If *SRLX is defined outside the *MATE block and the same value is used for all materials.

Best Practices: This option should be used for mechanical analyses of Ti-6Al-4V with r1 set to the stress relaxation temperature of 690o C.

*ANNL: Anneal Temperature

*ANNL

r1

r1: r*8: Anneal temperature

- When the temperature exceeds r1, plastic strain is set to zero.

- If *ANNL is defined outside the *MATE block and the same value is used for all materials.

This option incorporates material annealing (erasing of dislocations at high temperatures) at temperature r1 (in oC) into the mechanical analysis.

*EVAP: Evaporation Temperature

*EVAP

r1

This option specifies the evaporation temperature (in oC) for the deposited material and is listed outside the material block.

*TCUT: Temperature Cut-Off Value

*TCUT

r1

r1: r*8: temperature cut off value

- Used in mechanical analyses to neglect temperatures higher than melting.

- Temperatures above r1 (oC), are clipped to the r1 value.

- This card can minimize excessive plasticity and improve convergence for mechanical analyses.

- Currently *TCUT is defined outside the *MATE block and the same value is used for all materials in the analysis.