In this step, we inspect the safety factor at the time step with the maximum stress value.

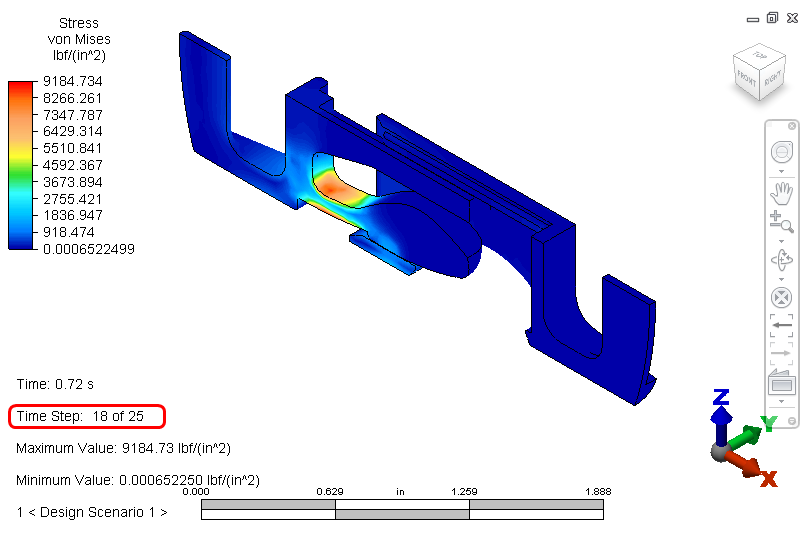

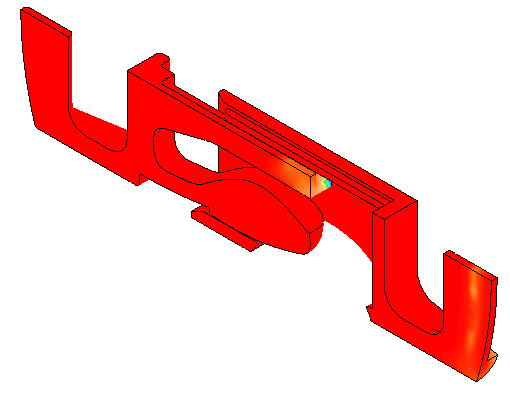

Continuing from the previous page, the Von Mises stress for Time Step 18 should be displayed as shown in the following image:

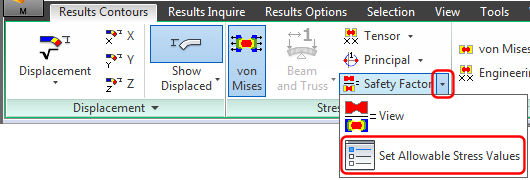

- Switch to the

Results Contours tab, and in the

Stress panel, click the arrow beside

Safety Factor, and click

Set Allowable Stress Values in the drop-down menu.

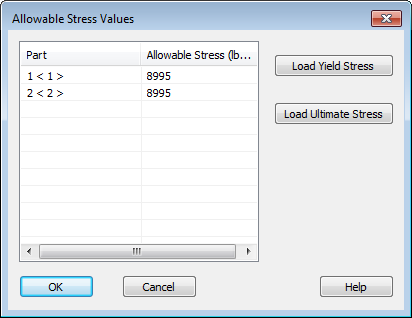

The following dialog box appears:

Note that the allowable stress values are already defined. By default, the allowable stress value of each material is set according to the yield strength. Alternatively, you can choose to base the safety factor results on the material ultimate strength. For the polycarbonate material used in this model, the ultimate stress is only very slightly greater than the yield strength. For metals, there is generally a much more significant difference between the yield and ultimate strength.

- Click OK to close the Allowable Stress Values dialog.

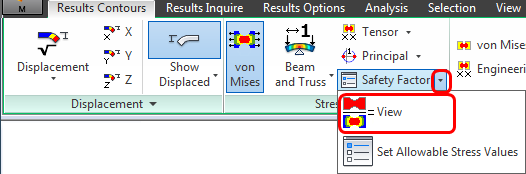

- Once again, click the arrow beside

Safety Factor

and this time, click

View in the drop-down menu.

You should see this:

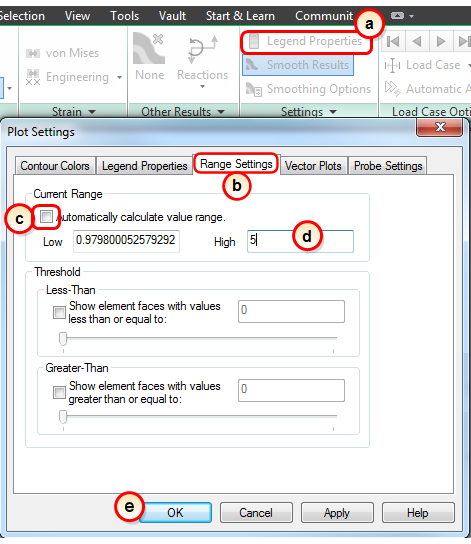

- This plot doesn't show us much, so let's adjust the legend range:

- Click Legend Properties.

- Go to the Range Settings tab.

- Uncheck Automatically calculate value range.

- Enter 5 as the High value.

- Click OK.

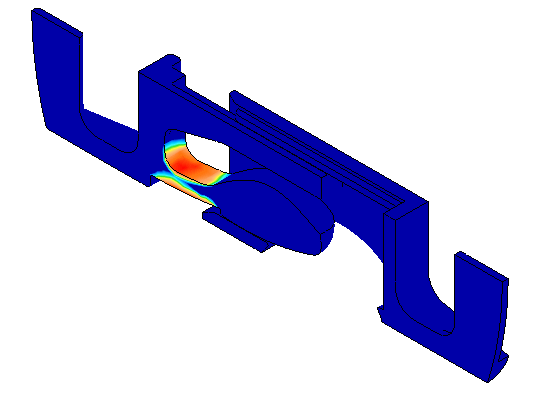

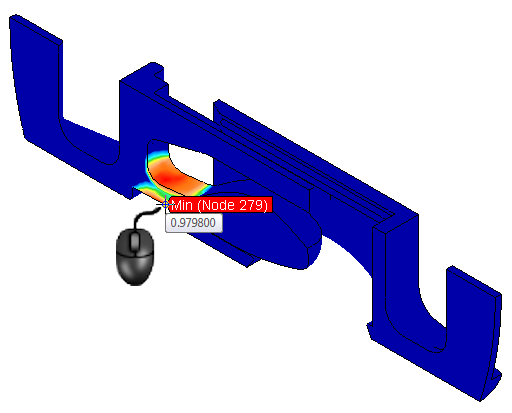

You should see this:

From the plot legend, we can see that the minimum safety factor is slightly less than 1, which indicates that the yield strength has been exceeded. The area of concern is where the latch finger on the clip bends. The spring clip is most likely to fail at this location.

- To precisely locate the minimum safety factor, and to probe for specific values, do the following:

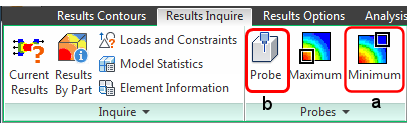

- Click

Results Inquire Probes Minimum to place a probe on the node with the lowest safety factor. Notice that the node number is the same as previously identified as the maximum stress node.

- Click

Results Inquire

Probe, and hover the mouse in the region of the lowest safety factors (red areas). At the point of the

Minimum

probe, the probe tool shows the same value as you see at the bottom of the plot legend.

Probe, and hover the mouse in the region of the lowest safety factors (red areas). At the point of the

Minimum

probe, the probe tool shows the same value as you see at the bottom of the plot legend.

- Click

Results Inquire Probes Minimum to place a probe on the node with the lowest safety factor. Notice that the node number is the same as previously identified as the maximum stress node.

Wrap Up

In a few short minutes, you conducted a complete mechanical event simulation of a spring clip assembly. You assigned materials, contacts, and constraints, and created views that help to understand the behavior of the device.